What are pressure reducing valves and what is their importance?

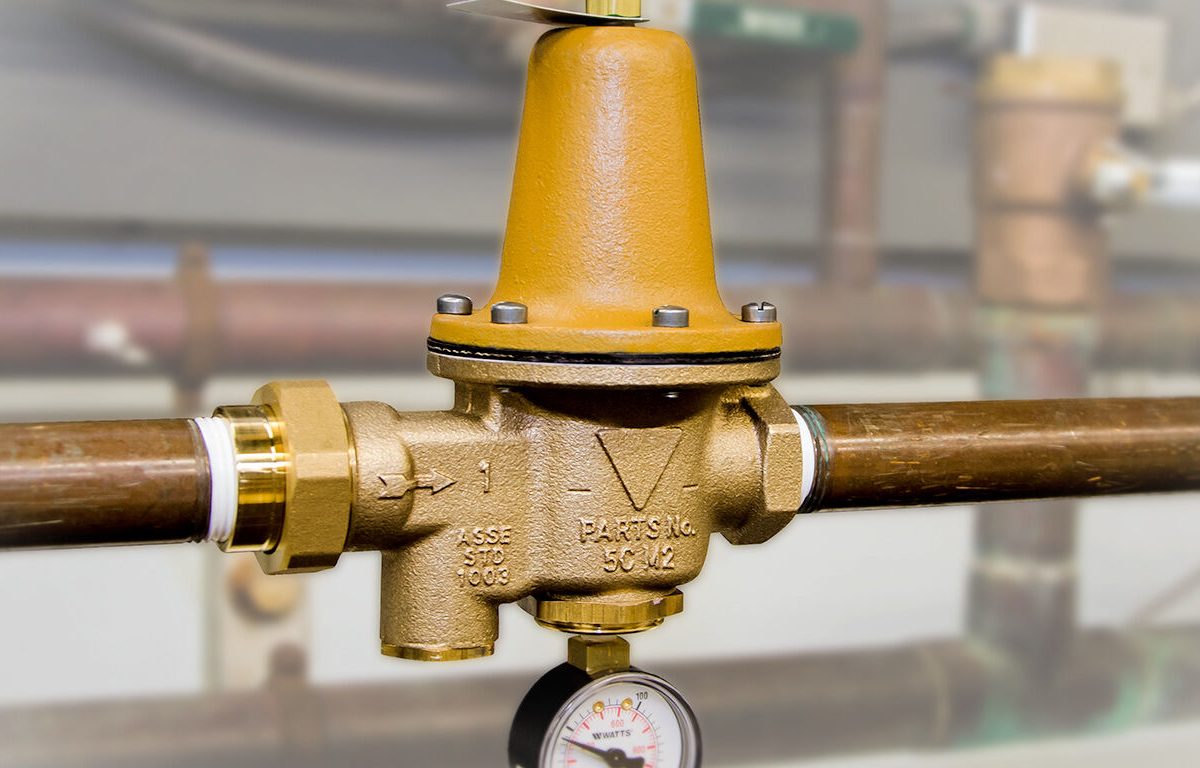

Pressure reducing valves are designed to reduce the pressure of incoming water or steam to a safer and predetermined level. Depending on the type of valve, the pressure is regulated in the direction of water flow either by adjusting the pressure on the valve or through an external sensing device. Pressure reducing valves are used in residential, commercial, institutional, and industrial applications.

Importance of Pressure Reducing Valves (PRV):

- Pressure reducing valves are installed in residential, semi-commercial, and public buildings to reduce and stabilize the incoming water pressure.

- If the main or booster water pressure is too high, the heating system may not function as intended, and the components in the system may be prone to damage.

- The force of water from a faucet or another outlet, for example, maybe too vigorous, which can cause water splashback.

- Pressure reducing valves are designed to reduce and maintain water pressure at a specified level to prevent damage to those downstream components installed after the pressure reducing valve.

Operation Mechanism of Pressure Reducing Valves:

- Pressure reducing valves work by reducing the pressure in the hydraulic system to a predetermined and constant level. This is achieved by adjusting the flow of hydraulic fluid and directing it through the valve.

- When the pressure in the system exceeds the set level, the pressure reducing valve is activated. The valve contains a set of internal elements, including a ball or disc, springs, and other hydraulic components.

- If the pressure is above the set level, the hydraulic fluid starts to flow through designed passages inside the valve. The ball or disc reduces the area of the passages, thus reducing the flow of fluid. This leads to a reduction in pressure in the system.

- On the other hand, when the pressure is below the set level, the springs inside the valve are adjusted to allow for a greater flow of hydraulic fluid, thereby increasing the pressure in the system.

- In this way, the pressure reducing valve works to maintain a specified and constant pressure in the hydraulic system. This helps protect hydraulic components and equipment from excessive pressures and ensures smooth and efficient operation of the hydraulic system.

Where should a pressure reducing valve be installed?

A pressure reducing valve should be installed after the main isolation valve at the entry point of cold water. In residential applications, it may also be installed after the main inlet valve of the continuous hot water system. Care should be taken regarding the installation location of the valve so that you have sufficient space to accommodate the valve.

The Primary Functions of Pressure Reducing Valves:

Most circuit designers use systems designed effectively to prevent system pressure rise and pump flow during standby periods. In this way, hydraulic system damage, excessive hydraulic fluid temperature, and electrical waste are avoided. This is where pressure reducing valves are used.

Pressure reducing valves are used in hydraulic systems to deal with the power generated by the actuator. Actuator power is produced by a hydraulic motor that consists of a cylinder or a fluid motor that utilizes hydraulic power to enable mechanical work. Valves are also used to determine and select pressure levels. The following are a number of different functions for these valves:

- Reducing system pressure and relieving it.

- Lowering pressure levels from the main circuit to the sub-circuit.

- Regulating system pressure in specific parts of the circuit.

- Preventing the maximum system pressure from reaching an unsafe level.

- Other pressure-related functions involve pressure control.

- Assisting in the sequencing of motor operations in a circuit using pressure control.

- Protecting the system from excessive system pressures. It also determines the operating pressure for some system functions.

- Maintaining high pressures even with varying input pressures.

- The main purpose of a pressure control valve is to provide safety in the workplace.

- Preventing potential damage from excessive pressures on equipment.

- In this way, workers or users of any pressure equipment are protected.