Advantages of using MBBR technology in wastewater treatment

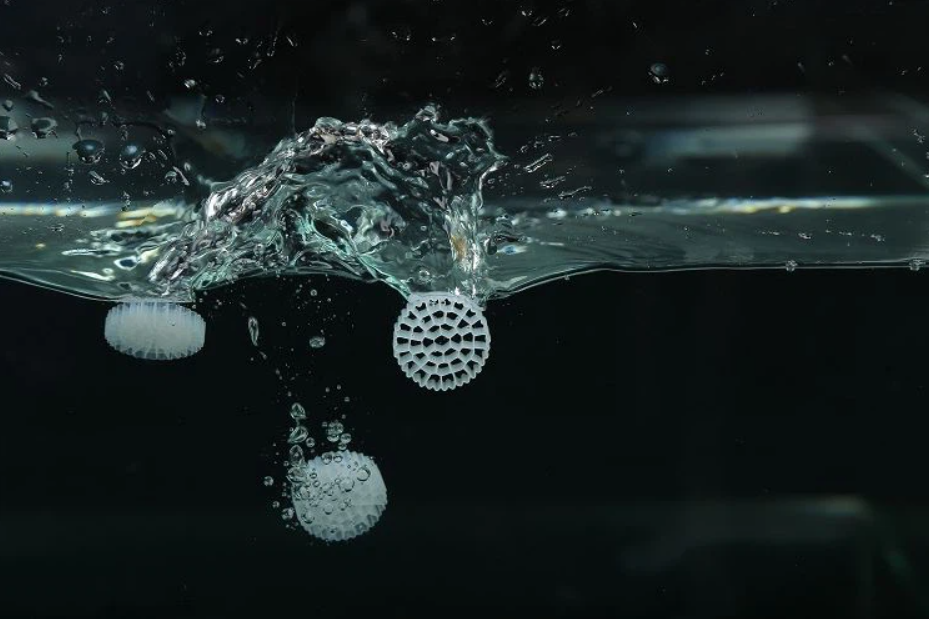

The advantages of using MBBR technology have emerged in several applications. where The MBBR technology combines a unique fully open and fully protected biomass carrier with a highly efficient aeration and mixing design. This results in superior effective surface area for biomass growth and optimal oxygen transfer efficiency.

The MBBR technology is a result of more than a decade of intensive multidisciplinary research and development. Integrating Fixed Film and Suspended Growth Technologies. It is considered the ‘next-generation’ in biological wastewater treatment methods.

Key advantages of using MBBR technology

- Excellent effluent results.

- Low operating costs due to highly efficient moving bed biofilm reactor

- Fully automatic operation with minimum maintenance

- Long lifetime of equipment

- Minimal daily operational requirements

- Small footprint

- Fast deployment

- Scalable and simple operation

- Flexible and innovative technology

- Durable and stable

- Intensive nitrification

- Environmentally friendly

- Strong ongoing support for operations and after-sales service by trained technicians.

Advantages of using MBBR technology in several applications

Capacity Increase

Municipal: The municipality is required to increase the capacity of its wastewater plant due to increased flow load and natural population growth.

Industrial: The industrial plant is required to handle larger quantities of wastewater due to increased production capabilities.

The MBBR Solution: increases the capacity of the wastewater plant by up to 50% without additional construction. The solution offers rapid deployment and minimal downtime.

Quality Improvement – BOD and Nitrogen Removal

Municipal: The municipality is required to improve the effluent quality to meet new stringent regulatory requirements.

Industrial: The industrial plant is required to produce a higher quality effluent due to increased regulatory requirements or implementation of water-saving measures.

The MBBR Solution: alters the biological environment, creating optimal conditions for enhanced removal of a wide variety of pollutants, including BOD and total Nitrogen removal.

Fast Recovery from Process Upsets

Municipal: The municipality experiences process upsets caused by shock load or storm-water hydraulic peaks, as well as toxic elements from industrial influent.

Industrial: The industrial plant experiences process upsets caused by shock loads, toxic materials, and influent variations (peaks), such as

seasonal fluctuations.

The MBBR Solution: operates as a buffer to streamline variable inflow and organic loads, preventing biomass washout while promoting rapid recovery from toxic shocks.

Limited Footprint

Municipal: The municipality faces space constraints when designing the new wastewater treatment plant.

Industrial: The industrial plant is usually limited in space, as it cannot expand its site.

The MBBR Solution: offers significant space efficiencies in the implementation of new reactors with a 30%-60% reduction in reactor volume, compared to conventional systems.

Future Expansions when using MBBR technology

Municipal: The municipality is forced to design an oversized plant to cope with uncertain future demand increases.

Industrial: The industrial plant needs to invest in an oversized plant today to handle future growth.

The MBBR Solution: offers the ability to gradually increase capacity by simply adding biomass carriers. Clients can increase the capacity of existing reactors at exactly the rate that is needed with ‘just-in-time’ capital investment.

Minimize process complexity and operator attention

Municipal: Remote locations and small communities lack the technical resources for intensive operation of the facility.

Industrial: The Industrial plant has limited wastewater treatment operations resources and requires a simple-to-operate solution with minimal ongoing attention.

The MBBR Solution: can avoid or significantly decrease sludge circulation, reducing the ongoing operation attention needed.