What are Metal seated gate valves?

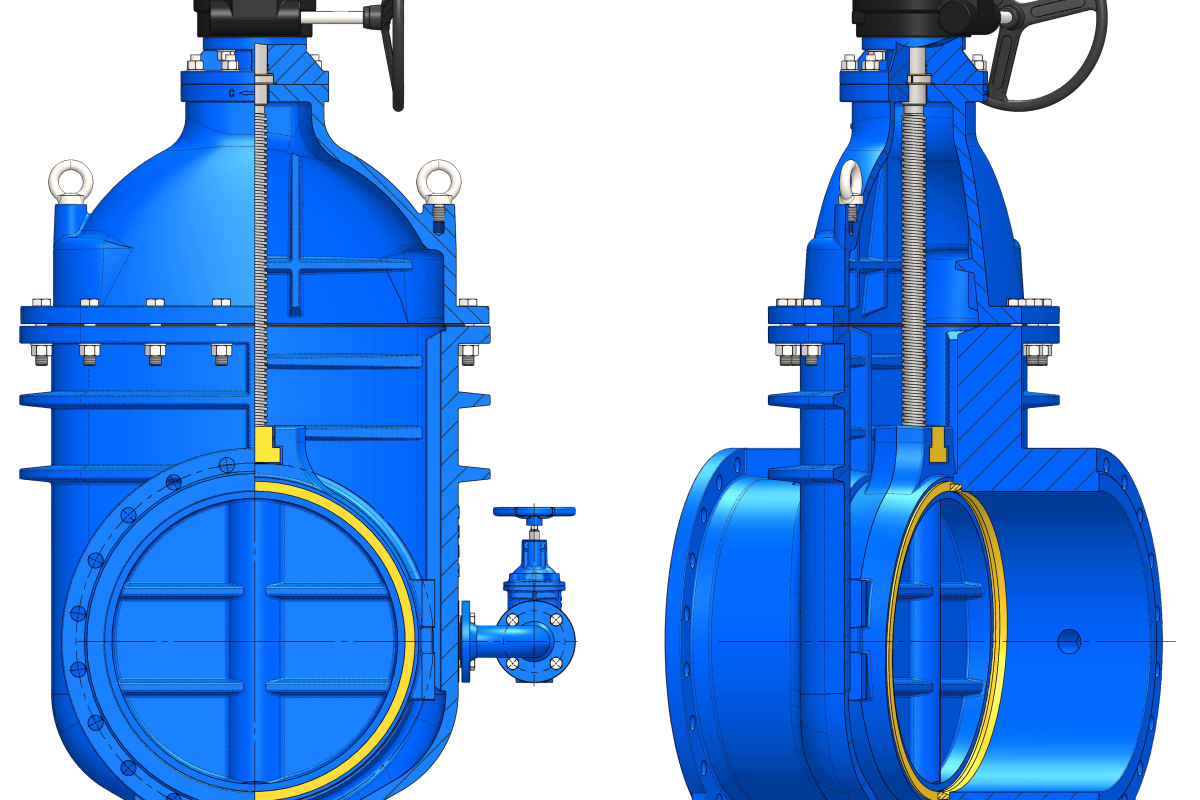

The Metal Seated Gate Valves are primarily designed for isolating flow along a pipe or equipment piece. It utilizes a gate made of flexible metal containing bronze rings to provide a tight water seal. Gate valves are valves that allow fluid to pass through and stop the flow by the movement of the gate, also known as the disc, in the vertical direction using a threaded stem. Gate valves are not throttling valves and must be fully open or fully closed. The seal is provided by metallic materials on the sliding and body. Thanks to this feature, it can be used in applications requiring high temperatures.

Materials Used in Manufacturing Metal Seated Gate Valves:

Metal Seated Gate Valves use various metallic materials to provide sealing and durability. Materials such as Stainless Steel, Cast Iron, Bronze, and Nickel are commonly used in gate and body parts. The suitable material is selected according to the specific application and working conditions, such as temperature, pressure, and the medium being circulated in the pipe or equipment. Corrosion-resistant and high-temperature materials are particularly chosen to ensure long-term performance and maintain a tight seal.

Common Materials Used for High-Pressure Bearing in Gate Valves:

Several common materials are used for bearing high pressure in gate valves. Among these materials:

- Cast Steel: Cast steel is a common choice for gate valves exposed to high pressures. It is characterized by durability, high strength, and the ability to withstand harsh conditions.

- Stainless Steel: Stainless steel is used in gate valves exposed to corrosion or strong chemical medium. It is resistant to rust, corrosion, and chemical corrosion.

- Cast Iron: Cast iron is used in gate valves with medium to high pressure. It has good durability and high strength and can withstand high pressures well.

- Bronze Alloys: Bronze alloys are used in gate valves to withstand high pressure and corrosion. They are resistant to corrosion and can handle high temperatures.

- Nickel Alloys: Nickel alloys are used in gate valves exposed to high pressure and strong corrosion. They are known for their strength, corrosion resistance, chemical corrosion resistance, and high temperature.

Factors for Choosing the Right Material in Metal Seated Gate Valve:

When choosing the right material for a metal seated gate valve, several factors must be considered. Here are some important factors to consider:

- Temperature: Ensure that the selected material can withstand the expected temperature without affecting the valve’s performance. Some applications require materials that withstand high temperatures, such as heat-resistant steel.

- Pressure: The material should be able to withstand the expected pressure in the pipeline or equipment without deformation or damage. Choose a material with high-pressure resistance.

- Operating Medium: Take into account the medium being circulated. Some media may be highly corrosive and susceptible to corrosion or contain special chemicals. Choose a material that is compatible with the operating medium and resistant to corrosion and chemical corrosion.

- Cost: Consider the cost of the selected material and compare it with the specific requirements of the application. Find a balance between performance and cost to get the best possible value.

- Maintenance: Consider the ease of valve maintenance and replacement of any damaged parts. Prefer materials that require less maintenance and are durable in the long run.

By choosing the right material according to these factors, the effective and reliable performance of the metal seated gate valve can be ensured in the specific application. Therefore, at CareWater, we ensure to provide various types of valves made of the highest quality materials and the latest technologies.