What are ball valves and what are their different types?

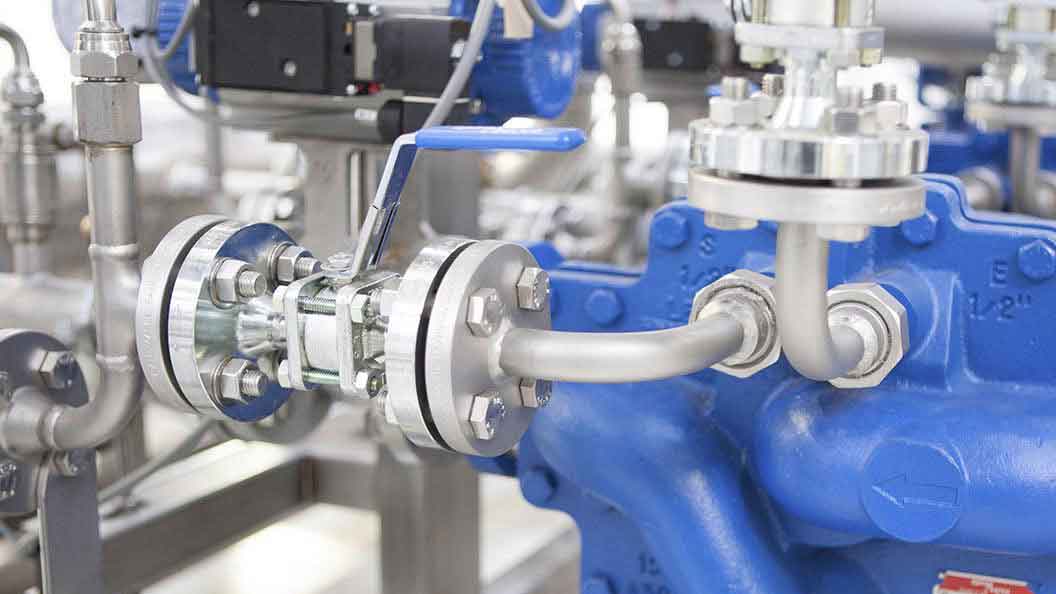

Ball valves use a metal ball that has a hole running through the center. It is placed between two seats to control the flow of fluids. They are used in many hydrocarbon processing applications. Ball valves have the ability to control the flow of gases and vapors and are particularly useful in low-flow situations.

The ball valve consists of a valve body in which a large ball is installed and a central hole that is the size of the inner pipe diameter. When the ball is rotated, in the fully open position, the valve provides an open passage or full orifice allowing unrestricted flow of liquids and detergents. Compared with a gate valve, a ball valve has very little resistance to flow in the fully open position. A ball valve, like a gate valve, is generally used in the fully open or fully closed position.

Ball valves type:

There are many types of ball valves, including:

Soft sealing ball valve

The “classic” ball valve is a soft seal and is still the most widely used today due to its flexibility. Seals (balls) are made of plastic, most often polytetrafluoroethylene (PTFE). PTFE sealing rings are suitable for most liquids and gases and can be used up to +200°C, also up to +260°C depending on additives.

Soft seal ball valves are not suitable for media containing solid particles or for high operating temperatures.

Metal seal ball valve:

Metal ball valves are used in applications involving the passage of solids or at high operating temperatures. Seal rings are made of stainless steel or high-strength alloy steel, and in some cases, they are additionally hardened. Metal seal ball valves are suitable for operating temperatures up to approximately +650°C.

Ball Valve Design:

Types of ball valves In terms of body design, there are the following types:

Single body ball valve:

The body is made of only one piece, the passage is reduced and the connection type is only an internal thread.

Double body ball valve:

The two body sections are connected together with screws, there can be full-passage or moderate-passage versions, and all types of connection are possible.

Three-part ball valve:

The ball valve consists of three parts (inner, middle, and outer parts). This design is easy to maintain, as the center section can be easily removed for complete replacement or individual closing parts. It improves performance and provides a better user experience.

Advantages and disadvantages of ball valves:

Below are the main advantages of ball valves:

- Due to its design, the ball valve has a compact structure.

- Opening and closing is very fast by rotating 90 degrees.

- Full passage ball valves are easy to clean.

- Withstands high temperatures and high pressures.

- Very high flow rates, Kvs, and only low-pressure losses can be achieved.

- Manufactured to strict specifications providing a tight seal and less maintenance.

- A wide range of sizes, materials, and body design options are available to provide a suitable model for any application.

- Precision design provides integrated valves.

- Operation and maintenance are easy thanks to quarter-turn opening and closing.

- Low torque valves with small actuators for automation.

- Unrestricted flow allows for lower pressure and increased capacity.

- A corrosion-resistant body ensures long product life.

Disadvantages you can encounter when using ball valves

- The sealing surface of ball valves may wear quickly.

- At high pressures or large volumes, the axis must be boring, resulting in increased manufacturing costs.

- High pressure may occur in the piping system when the ball valve is closed too quickly.

- In a standard ball valve, the working medium can enter the effective space of the ball valve. The center enters the area between the body and the ball in a partially open position; This region is referred to as space. The medium is trapped in that region and is not able to expand in case of temperature fluctuations. This can eventually lead to damage to the seal and ball system and thus to operational problems.