Types of membranes inside a reverse osmosis plant

Today we dedicate our article to talking about the types of membranes in the reverse osmosis plant, because of their paramount importance in the efficiency of the plant. It is one of the most important elements in the water plant. As a continuation of the group of articles in which we discuss the components of a reverse osmosis plant, they are as follows:

What are the principles of choosing the right water valve?

Importance of water pumps in RO plants

CELLULOSE ACETATE

- Tolerance to chlorine.

- Not resistant to bacteria.

- The pH ranges between 6 and 8.

- Good water production rate.

- It should be used with water containing a certain percentage of chlorine.

- One of the most common types of membranes in the market.

CELLULOSE TRI-ACETATE

- Tolerant of chlorine.

- It tolerates many types of bacteria.

- The pH ranges between 4 and 8.

- Excellent water production rate.

- The use of water containing chlorine prolongs its life.

THIN FILM COMPOSITE

- Sensitive to chlorine, it must be removed before the water reaches the membranes.

- Resistant to bacteria.

- The pH ranges between 3 and 11.

- One of the most water-producing types of membranes.

- High salt rejection property.

- Long service years if the correct operating specifications are provided.

Describe the different types of membranes inside a reverse osmosis plant

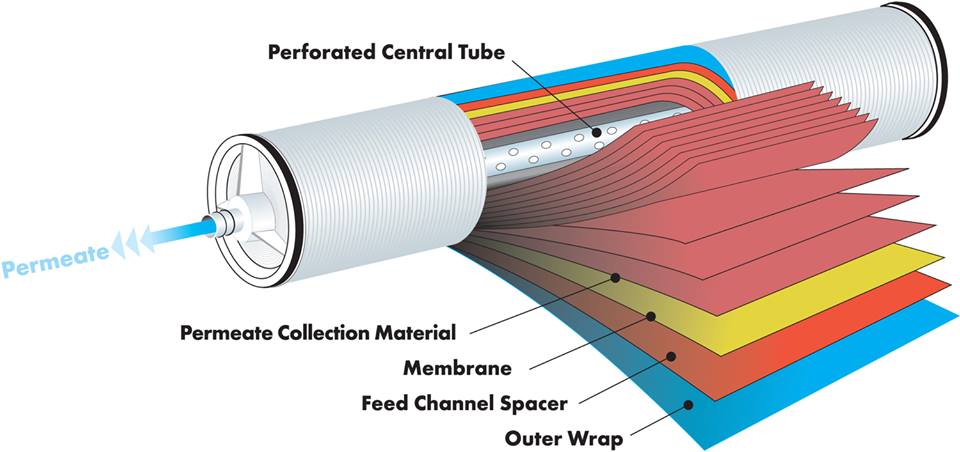

The membranes you see in a reverse osmosis unit inside pressure vessels are made up of several layers:

- An outer layer that acts as a support for the membrane, just like the function of an outer wrap that holds the message or letter inside.

- A wide network of pores allows feed water to enter the membranes and this layer is called a feed channel spacer, or a water inlet spacer, or a water inlet spacer in Arabic. We mention here the word “pores”, not the pores that other filters such as microfilters feature.

- Permeation of water through the membrane is through these spaces or spacers.

- This is followed by the Membrane layer itself.

- Then another narrow network called permeate spacer or water production spacer or productive water separator allows the collection of desalinated water to the central part where the permeate water is collected in the permeate collection tube … and this separator is isolated from 3 sides and thus can direct the desalinated water to the central collection tube.

Feed spacer function

The first function is to provide the water flow path (direct it to the correct path)

The second function is to increase the turbulence of the water on the surface of the membrane, which reduces the concentration polarization, thus reducing the possibility of salt deposition on the membranes.

Through the feed spacer nets, the water trapped behind the membranes continues its journey to exit from this system, where the salts have been concentrated (feed out) to enter the next membrane and so on.

Division of membranes according to their geometry

When the membrane is formed, we call it the module … and it is divided into four types according to the geometry or the Configuration:

Spiral wound module

This is the traditional and best-known type, in which these films are formed as wide helical plates in successive layers with reinforced materials such as an “envelope”.

These panels are wrapped in a steel tube and this rigid tube is a perforated steel tube. It is installed in the middle part of the pressure vessel, and permeate water flows in it, as we mentioned, and it is also called the Permeate collection tube.

This design helps to increase the surface area in the least amount of space. Its cost is low, but the disadvantage is its sensitivity to pollution and the difficulty of maintaining it due to the way it is made.

What happens is that the feed water enters spaces called feed spacer and then penetrates the membrane to enter through other channels called spacer permeate channel between the layers of the membranes where filtered water or permeate flows in spiral paths and from there to the inner tube in which permeate water collects.

Another name for the spacer permeates channel is the permeate water carrier…because it carries permeate water to the inner tube.

We note the presence of supporting layers (stents) wrapped in a spiral with the membranes to stabilize and protect them from changing pressures or increasing the intensity of loading on them.

Hollow fine fibers module (HFRO)

It is similar to hollow head hair strands, and it is a cover or shell that carries inside it a large number of tubes or hollow fibers collected in bundles and has a diameter of 0.1 to 2 millimeters. When it enters the feeding water through the openings of the fibers (open cores). The water penetrates the wall of the fibers and releases the permeate in the surrounding area (not from the middle as in the spiral plate).

Because these hollow filaments do not allow turbulent flow to occur, they are more prone to flaking or scale formation and are difficult to chemically clean. Therefore, it is often used with seawater, as the possibility of fowling is weak. Its use with brackish water is limited.

Tubular membrane

This type is also used with viscous or poor-quality water. Which does not need a primary treatment for the feed water. And works at very high pressures that may reach 100 bar.

From the name, we conclude that each membrane is placed in a perforated tube. And these tubes are assembled together like a bundle in what is called a Module.

The diameter of the tube ranges from 4-25 mm.

The feed water enters the pipes and the permeate that permeates through the membranes comes out of the side holes to be collected … and the reflux water comes out from the other end of the pipes.

The diameter of the tube ranges from 4-25 mm.

The feed water enters the pipes and the permeate that permeates through the membranes comes out of the side holes to be collected … and the reflux water comes out from the other end of the pipes.

Laminar Membranes

Where the membranes are in the form of parallel longitudinal sheets.