The Reason for the Difference in Valve Types Between Stages of a Single Wastewater Treatment Plant

The differences in valve types used in the various stages of wastewater treatment plants are essential for the efficiency and effectiveness of the treatment processes. Wastewater treatment plants perform the vital function of purifying water from domestic, industrial, and commercial sources, ensuring compliance with environmental standards before discharge or reuse. The treatment process is typically divided into four stages: pre-treatment, primary, secondary, and tertiary. Each stage requires specific types of valves to efficiently manage fluid flow and pressure, reflecting the varying operational requirements of each stage.

Valves in wastewater treatment plants are selected based on the unique characteristics and functions required at each stage. For example, pre-treatment typically uses gate valves and butterfly valves for effective flow control. Primary treatment relies on non-return and control valves to maintain sedimentation processes. Secondary treatment utilizes diaphragm and solenoid valves to enhance biological processes, while tertiary treatment may include needle and vent valves to ensure advanced purification.

The importance of choosing the right valves

Strategic valve selection is crucial for maintaining operational efficiency, preventing backflow, and regulating flow rates across various plant systems. Valve type selection is influenced by factors such as fluid properties, pressure and temperature ratings, and specific treatment plant requirements. Cost considerations and safety standards also play a vital role in the valve selection decision. Ensuring compatibility with different media and operating conditions is essential to prevent leaks, equipment failures, and non-compliance with regulations.

The selection process reflects the complexities of wastewater management and underscores the need for tailored solutions to enhance treatment efficiency and system reliability. As wastewater treatment technologies evolve, discussions continue regarding the effectiveness and environmental impact of different valve types. These discussions often focus on improving valve materials and designs for sustainability, particularly given increasing regulations and the need for efficient resource management in treatment plants.

Understanding these dynamics is critical for engineers and operators responsible for maintaining and optimizing the operational performance of wastewater treatment systems. This is what we strive to provide to all our clients at the CareWater Establishment for Water Purification.

Overview of Wastewater Treatment Plants

Wastewater treatment plants are essential facilities designed to treat and purify wastewater from domestic, industrial, and commercial sources. These plants utilize multiple treatment stages to remove contaminants and ensure that the treated water meets regulatory standards before being discharged back into the environment or reused. The treatment process is typically classified into four main stages: primary treatment, secondary treatment, and tertiary treatment.

Types of Treatment Plants

Domestic Wastewater Treatment Plants

Domestic wastewater treatment plants focus on treating domestic wastewater. The process generally involves several steps, including filtration, grit removal, primary sedimentation, secondary sedimentation, and tertiary sedimentation. The main objective of domestic wastewater treatment plants is to effectively reduce the biological oxygen demand (BOD) and remove suspended solids from wastewater.

Industrial Wastewater Treatment Plants: These plants use similar methodologies to domestic wastewater treatment plants but incorporate advanced technologies to achieve a lower BOD level in the treated water. This allows for stricter compliance with environmental regulations, making wastewater treatment plants crucial in areas where industrial waste poses a significant risk to water quality.

Combined and Integrated Wastewater Treatment Plants (CETPs)

Combined and integrated wastewater treatment plants handle wastewater from multiple sources, combining domestic and industrial wastewater for treatment. The process typically involves a two-stage approach, where the wastewater is allowed to settle for a period of time, allowing larger particles to settle to the bottom. This method effectively removes suspended solids and other contaminants, improving the overall efficiency of the treatment process.

Treatment Stages

Pre-treatment

The pre-treatment stage acts as the first line of defense, removing large objects and sediment to protect subsequent equipment. This stage utilizes bar screens and sedimentation chambers to separate inorganic materials, ensuring that subsequent processes can operate efficiently without interruption.

During pre-treatment, the focus is on the physical removal of solids through sedimentation. This process can remove up to 80% of the incoming solids, leaving the liquid component to proceed to secondary treatment. The solids that settle to the bottom are removed as sludge, which is then further treated.

Secondary Treatment

The secondary stage utilizes biological processes to reduce nutrient content, particularly ammonia and phosphorus. Microorganisms break down organic matter using various methods, including activated sludge and oxidation ponds. This stage is crucial for removing contaminants that were not adequately treated during primary treatment. The choice of valve type is influenced by the specific functions required at each stage, the properties of the fluids used, and operating conditions such as pressure and flow rate.

Common Valve Types

Globe Valves

Globe valves are widely used in wastewater treatment due to their design. Simple and efficient operation. These valves operate on a quarter-turn mechanism and feature a ball disc that allows or prevents fluid flow through an opening in the ball. This mechanism enables quick and reliable control of opening and closing, making globe valves suitable for isolation and shut-off points in processing operations. Their ease of operation and ability to provide a tight seal are particularly beneficial for applications requiring minimal leakage and maintenance, making them ideal for downstream industries, chemical storage, and oil and gas.

Butterfly Valves

Butterfly valves are compact and lightweight, designed for large-diameter pipelines, making them ideal for water distribution systems and treatment plants. Similar to ball valves, butterfly valves operate on a quarter-turn mechanism, using circular plates to open or close the pipe flow. Their efficient design helps maintain constant flow rates, extending the lifespan of pumping systems and piping networks.

Check Valves

Check valves, also known as one-way valves, are crucial for preventing backflow within processing systems. They allow fluid to flow in one direction while automatically shutting off in case of backflow. This self-regulating mechanism protects pumps and processors from potential damage caused by backflow, ensuring smooth operation throughout the piping network. Different types of non-return valves, such as swing non-return valves and lever non-return valves, are selected based on the fluid type and operating requirements.

Ball Valves

Ball valves are designed for precise flow control and are often used in applications where fluid regulation is essential. These valves feature a spherical body and a movable disc that can adjust the flow through a zigzag path, providing a higher degree of control compared to other types. However, they are heavier and can cause significant pressure drops, making them less suitable for fluids containing particles or highly viscous materials.

Diaphragm Valves

Diaphragm valves are particularly useful in applications requiring high levels of contamination prevention. They use a flexible diaphragm to isolate the flowing fluid from the valve body, creating a leak-proof seal. This design is beneficial for regulating viscous fluids or those containing solid particles. Diaphragm valves can also be used in choke applications where precise control is essential.

Selection Considerations

When selecting valves for wastewater treatment plants, several factors must be considered, including the type of fluid, required flow rates, pressure ratings, and operating conditions. Different treatment stages may require specific types of valves to ensure efficiency and safety, reflecting the diverse requirements of modern wastewater management systems.

Valve Types by Stage

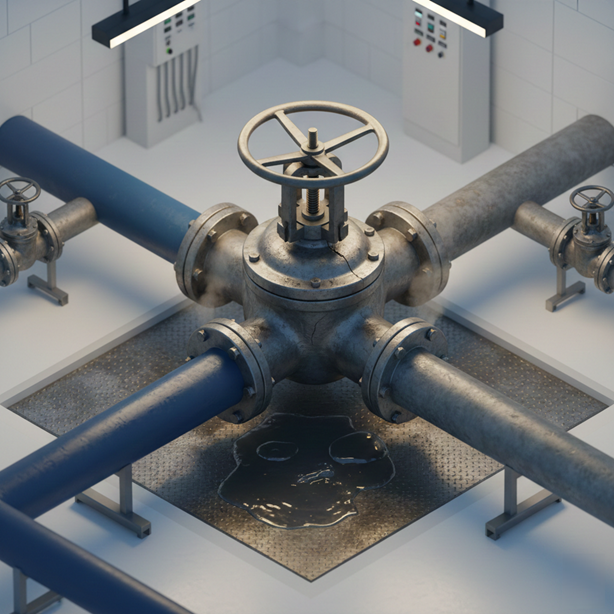

Valves play a crucial role in the operation of wastewater treatment plants, with specific types being selected for different stages of the treatment process due to their unique characteristics and functions.

Pre-treatment

In the pre-treatment stage, valves are primarily used to control water flow and manage the removal of large sludge and grit. Commonly used valve types in this stage include gate valves and butterfly valves, which allow for efficient flow isolation and control without a significant pressure drop. Gate valves are preferred for their low fluid resistance, making them ideal for isolating fluid flow in large pipelines, while butterfly valves are useful in applications with limited space. During primary treatment, the focus shifts to sedimentation processes that remove heavy solids from wastewater. Valves used in this stage include non-return valves and control valves, which help maintain appropriate flow rates and prevent backflow.

Control valves are essential for regulating flow through primary sedimentation basins, ensuring efficient sedimentation. Additionally, the valves must be made of materials resistant to corrosion and damage caused by the presence of solids in the wastewater.

Secondary Treatment

Secondary treatment typically involves biological processes to remove nutrients from wastewater. This stage requires valves capable of handling varying flow rates and pressures, as well as valves suitable for use in aeration systems. Common types include diaphragm valves and solenoid valves, which provide precise control of air and water flow within the treatment system. Using these valves ensures optimal conditions for microbial activity, allowing for efficient nutrient removal.

Tertiary Treatment

Tertiary treatment is an advanced stage designed to further purify wastewater, often removing more than 99% of impurities. This stage may require specialized valves, such as needle valves and pressure relief valves, which allow for precise adjustments to water flow and pressure control. Needle valves are particularly useful for controlling water flow in filtration systems, while pressure relief valves protect the system from overpressure, ensuring safe and efficient operation.

Factors Affecting Valve Selection

Valve selection in treatment plants is a critical process influenced by various factors that ensure operational efficiency, safety, and compliance with industry standards.

Fluid Properties

The properties of the treated fluid play a vital role in valve selection. These properties include chemical composition, temperature, pressure, and viscosity. For example, valves used in chemical injection lines must be compatible with strong chemicals such as sodium hypochlorite, necessitating the use of materials such as stainless steel or specialized polymers like polytetrafluoroethylene (PTFE) to prevent corrosion and damage.

Therefore, valves in drinking water applications may use food-grade epoxy-coated wrought iron to resist corrosion from treated water, reflecting the importance of material compatibility in different operating contexts.

Pressure and Temperature Ratings

Valves must be selected based on their pressure and temperature ratings to ensure they can withstand system operating conditions. Each valve type has a maximum allowable pressure and temperature; exceeding these limits may cause the valve to fail. It is essential to select valves that not only meet these requirements but also provide sufficient safety margins to accommodate changes in operating conditions.

System Type

The specific requirements of different system types—such as pumping stations, wastewater treatment plants, and water supply facilities—significantly influence valve selection. Each system type has unique operational requirements that determine the choice of valve types, including gate valves, ball valves, and non-return valves. For example, gate valves are often preferred for their low fluid resistance in large pipelines, while ball valves may be chosen for applications requiring precise flow rate control.

Cost and Economic Considerations

Cost is another crucial factor in valve selection. The total cost of ownership, including the initial purchase price, installation, maintenance, and any potential operational failures, must be carefully evaluated. The cost-effectiveness of a valve can vary significantly depending on its design and application. Making a thorough economic analysis is essential for informed decision-making.

Conclusion

Water Care: Expertise Selects the Best for You. The diversity of valve types is not merely a technical detail; it’s a strategy that ensures plant sustainability and purification efficiency. At CareWater for Water Purification, we leverage our extensive expertise to provide the highest quality valves compatible with every stage of treatment, guaranteeing safe operation and optimal performance for our clients.