Finding the best reverse osmosis membranes in KSA

At CareWater, we offer many water treatment solutions for all applications, starting with water treatment systems for different factories, which you can learn about from this article. To the needs of homes, restaurants, and small cafes. If a question arises in your mind: How do I find the best reverse osmosis membranes in the Kingdom, read this article carefully.

You can determine the quality of reverse osmosis membranes based on a number of factors. Such as the manufacturer, the extent to which the type of membrane matches your needs, and the availability of spare parts, maintenance, or after-sales service.

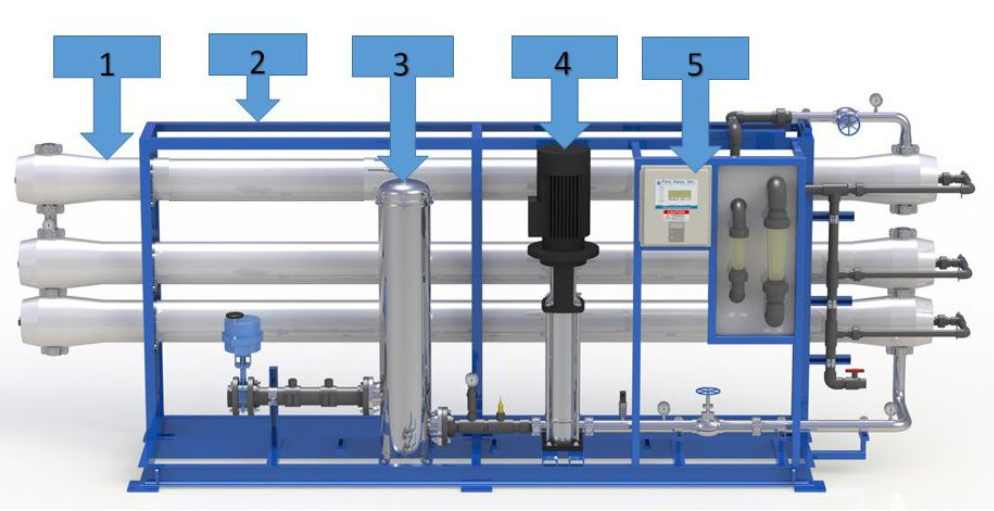

What are the basic components of a reverse osmosis system:

A reverse osmosis system consists of five basic parts, which we illustrate in this picture:

1) Pressure vessels and diaphragms

Obviously, a reverse osmosis system will not stray too far from the membrane elements. The proteins that make up the membrane elements vary depending on the type and amount of water and end in purity. There are membranes for saltwater, seawater, hospital-grade extreme disinfection, and membranes designed to remove specific contaminants to name a few. If there is a need for water treatment, you can be sure that there is definitely a membrane element for this. The size of the job (municipal, commercial, or industrial) determines the size and number of membranes in the system. There can be anywhere from a single one-and-a-half-inch membrane (as in an under-sink reverse osmosis system) to hundreds of eight-inch membranes all working together (a typical reverse osmosis plant).

2) Carbon steel frame

The best way to make your reverse osmosis system as durable as possible is with a powder-coated carbon steel frame to mount all of your components. It’s resistant to the elements designed for the heavy vibration of high-pressure pumps, and grounded to ensure it will last a lifetime.

3) Filter cartridge

Most reverse osmosis systems come with a cartridge filter to ensure that there are no particles large enough to damage the membranes anywhere near them. This cartridge is usually a five-micron polypropylene filter but can vary upon request. The cartridge comes in a durable housing that can handle pressure from the main feed or booster pumps.

4) Reverse osmosis high-pressure pump

Without a quality pump, the rejection rate for a reverse osmosis system is not viable in most commercial or industrial settings. It is necessary for the system to ensure that the pump matches the diaphragm quantity and size appropriately. Typically, the higher the measles strength of the intake pump, the better the rejection and recovery rates for permeability.

5) Control Panel

Finally, the reverse osmosis system must be controlled by a human operator. Via an advanced control panel or a solid-state microprocessor depending on how advanced the controls are. The controls can also be used to manage multiple systems simultaneously, making a single water production plant run efficiently.

Reverse osmosis systems can also have a number of other components built upon or in them as additional components as well. Can be fully integrated into a containerized system for example desalination with an RO system is always on the go. There are a number of add-ons that can be attached to an RO system as well, to perform tasks such as membrane cleaning, pretreatment, chemical dosing, and a number of other functions as necessary.

What types of commercial/industrial applications need reverse osmosis membranes?

If water treatment is needed, a reverse osmosis system will probably do the job. There is a wide range of industries that benefit from having high-purity water. As well as a large number of applications that require water treatment. Because of the large amounts of water required, a reverse osmosis system is often the ideal economical solution, requiring less energy than most large-scale treatment methods. Since it consumes less energy, a reverse osmosis system is an environmentally friendly solution as well.

- Boiler water treatment

- Food and beverage services

- Industrial wastewater purification

- Hotels and resorts

- Car washes

- Pure ethanol

- Dairy industry

- Pharmaceutical industries

- Water filling

- Hospitals

- Agriculture