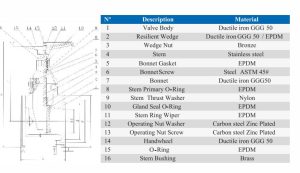

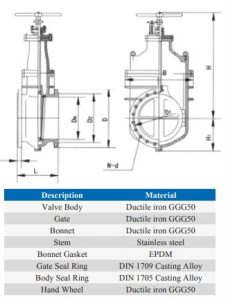

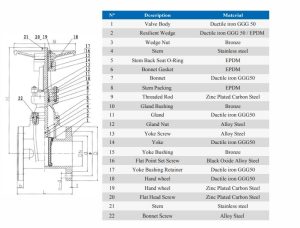

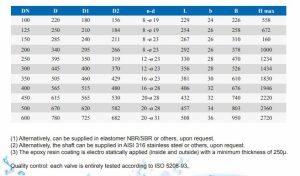

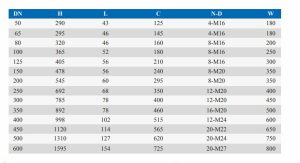

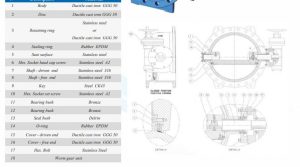

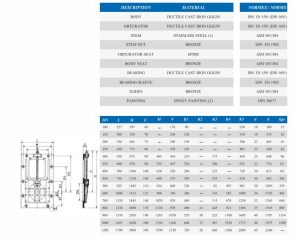

DOUBLE FLANGED

SOFT SEALING GATE VALVE

Confirms to DIN 3352

Working pressure PN 10/16

Testing pressure PN 16/25

Operating Tempreture 0°C to 71°C

Applications: Potable water, Sewage, Industrial waste water,

Air conditioning systems, Chilled water pumps, Fire and

Irrigation systems

(1) Alternatively, can be supplied in elastomer NBR/SBR or others, upon request.

(2) Alternatively, the shaft can be supplied in AISI 316 stainless steel or others, upon request.

(3) The epoxy resin coating is electro statically applied (inside and outside) with a minimum thickness of 250μ.

Quality control: each valve is entirely tested according to ISO 5208.

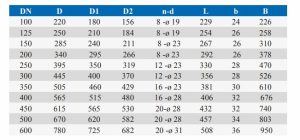

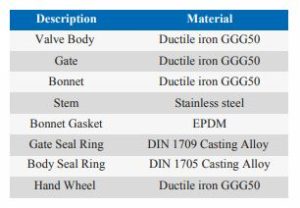

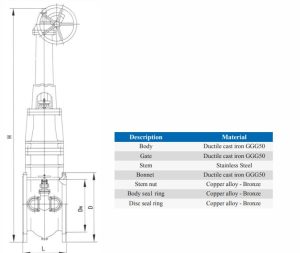

DOUBLE FLANGED METAL

SEATED GATE VALVE

Working pressure PN 10/16

Testing pressure PN 16/25

Design & Manufacture ISO 5996-96

Inspection & Test ISO5208-93

Flange Dimension ISO 2531-98

Max. Operating Temp. 80°C

Applications: Potable water, Sewage, Industrial waste water, Air conditioning systems, Chilled water pumps, Fire and Irrigation systems.

(1) Alternatively, can be supplied in elastomer NBR/SBR or others, upon request.

(2) Alternatively, the shaft can be supplied in AISI 316 stainless steel or others, upon request.

(3) The epoxy resin coating is electro statically applied (inside and outside) with a minimum thickness of 250μ.

Quality control: each valve is entirely tested according to ISO 5208

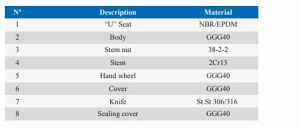

DOUBLE FLANGED

NON RISING STEM GATE VALVE

Confirms to BS 5150

Working pressure PN 10/16

Testing pressure PN 16/25

Operating Tempreture ≤ 80 °C

Applications: Potable water, Sewage, Air conditioning systems,

Chilled water pumps, Fire and Irrigation systems.

(1) The epoxy resin coating is electro statically applied (inside and outside) with a minimum thickness of 250μ.

Quality control: each valve is entirely tested according to BS 6755.

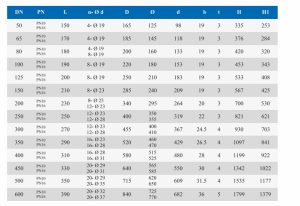

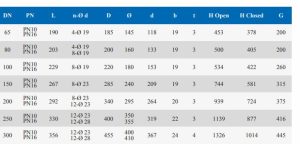

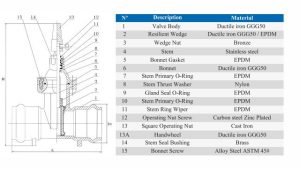

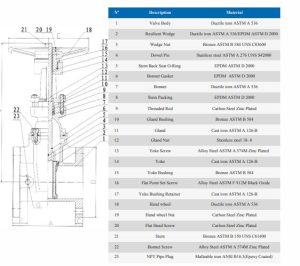

DOUBLE FLANGED

RISING STEM GATE VALVE

Confirms to BS 5163

Working pressure PN 10/16

Testing pressure PN 16/25

Operating Tempreture 0°C to 71°C

Applications: Potable water, Sewage, Air conditioning systems,

Chilled water pumps, Fire and Irrigation systems.

(1) Alternatively, the wedge can be supplied in elastomer NBR/SBR or others, upon request.

(2) Alternatively, the shaft can be supplied in AISI 316 stainless steel or others, upon request.

(3) The epoxy resin coating is electro statically applied (inside and outside) with a minimum thickness of 250μ.

Quality control: each valve is entirely tested according to ISO 5208.

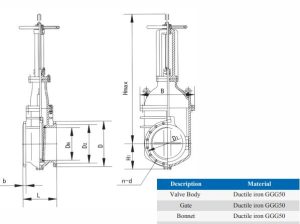

DOUBLE FLANGED

RISING STEM GATE VALVE

Working pressure PN 10/16

Testing pressure PN 16/25

Design & Manufacture ISO 5996-96

Inspection & Test ISO5208-93

Flange Dimension ISO 2531-98

Max. Operating Temp. 80°C

Applications: Potable water, Sewage, Industrial waste water,

Air conditioning systems, Chilled water pumps, Fire and

Irrigation systems.

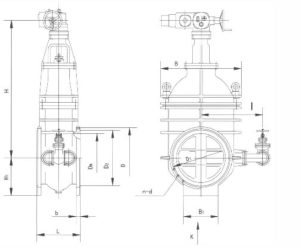

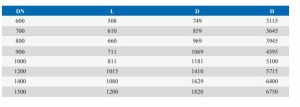

DOUBLE FLANGED

RISING STEM GATE VALVE

Working pressure PN 10/16

Testing pressure PN 16/24

Applicable temperature ≤ 120°C

Suitable for: Potable water, Sewage, Air conditioning systems,

Chilled water pumps, Fire and Irrigation systems.

Valves > 600mm will be supplied with by-pass and bevel gear

.

The valve can be operated as follow:

a) With gear box.

b) With electric actuator.

The epoxy resin coating is applied (inside and outside) with a minimum thickness of 250μ.

Quality control: each valve is entirely tested according to ISO 5208.

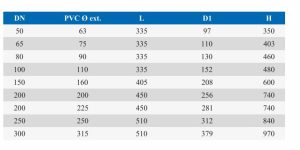

SOFT SEALING GATE VALVE

SOCKET ENDS FOR PVC

Confirms to DIN 3352

Working pressure PN 10/16

Testing pressure PN 16/25

Operating Tempreture 0°C to 71°C

Applications: Potable water, Sewage, Air conditioning systems,

Chilled water pumps, Fire and Irrigation systems.

(1) Alternatively, can be supplied in elastomer NBR/SBR or others, upon request.

(2) Alternatively, the shaft can be supplied in AISI 316 stainless steel or others, upon request.

(3) The epoxy resin coating is electro statically applied (inside and outside) with a minimum thickness of 250μ.

Quality control: each valve is entirely tested according to ISO 5208

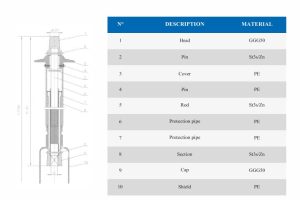

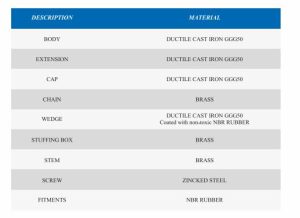

TELESCOPIC EXTENSION SPINDLE

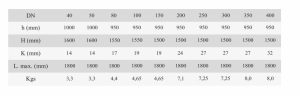

KNIFE GATE VALVE

Working pressure PN 10/16

Testing pressure PN 16/25

According to DIN 2501

Application : Potable water, Sewage, Air conditioning systems,

Chilled water pumps, Fire and Irrigation systems.

Quality control: each valve is entirely tested according to ISO 5208.

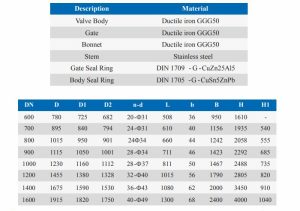

DOUBLE FLANGED

RISING STEM GATE VALVE

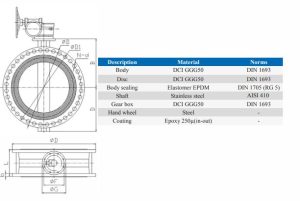

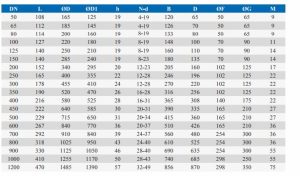

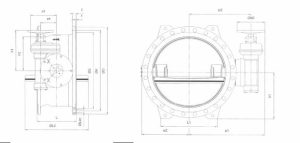

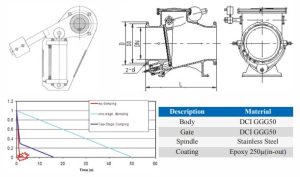

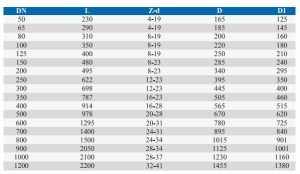

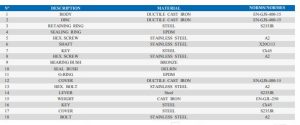

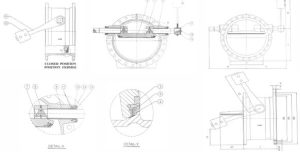

DOUBLE FLANGED BUTTERFLY VALVE

PNEUMATICALLY OPERATED

Working pressure PN 10/16

Testing pressure PN 16/25

Face-to-face dimensions ISO 5752 (BS 5155)

Application: Potable water, Air conditioning systems, Chilled water

pumps, Fire and Irrigation systems.

(1) Alternatively, the shaft can be supplied in AISI 316 stainless steel or others, upon request.

(2) The epoxy resin coating is electro statically applied (inside and outside) with a minimum thickness of 250μ.

(3) The valve can operated as following:

a-With gear box.

b-With electric actuator.

d-With pneumatic actuator.

e-With hydraulic actuator.

Quality control: each valve is entirely tested according to ISO 5208.

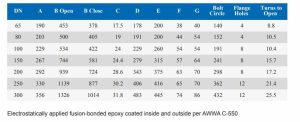

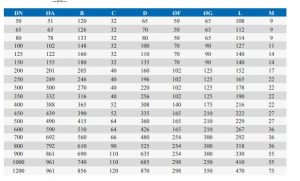

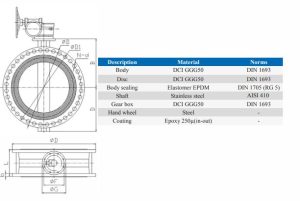

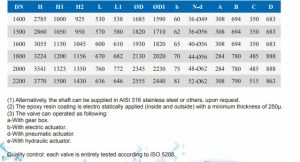

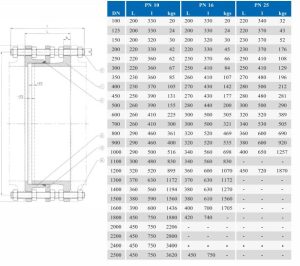

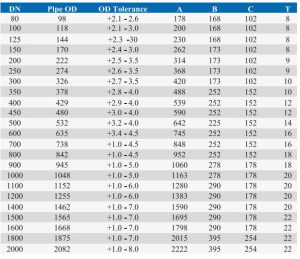

DOUBLE FLANGED

BUTTERFLY VALVE

Working pressure PN 10

Testing pressure PN 16

Face-to-face dimensions ISO 5752 (BS 5155)

Application: Potable water, Air conditioning systems, Chilled water

pumps, Fire and Irrigation systems

(1) Alternatively, the shaft can be supplied in AISI 316 stainless steel or others, upon request.

(2) The epoxy resin coating is electro statically applied (inside and outside) with a minimum thickness of 250μ.

(3) The valve can operated as following:

a-With gear box.

b-With electric actuator.

d-With pneumatic actuator.

e-With hydraulic actuator.

Quality control: each valve is entirely tested according to ISO 5208

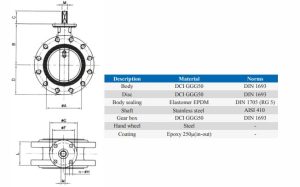

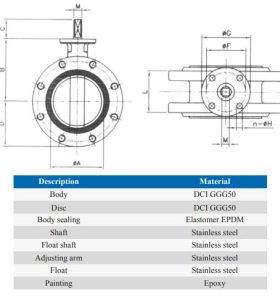

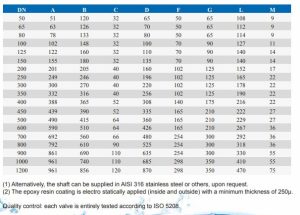

DOUBLE FLANGED

BUTTERFLY VALVE

Working pressure PN 10

Testing pressure PN 16

Face-to-face dimensions ISO 5752 (BS 5155)

Application: Potable water, Air conditioning systems, Chilled water

pumps, Fire and Irrigation systems.

(1) Alternatively, the shaft can be supplied in AISI 316 stainless steel or others, upon request.

(2) The epoxy resin coating is electro statically applied (inside and outside) with a minimum thickness of 250μ.

(3) The valve can operated as following:

a-With gear box.

b-With electric actuator.

d-With pneumatic actuator.

e-With hydraulic actuator.

Quality control: each valve is entirely tested according to ISO 5208

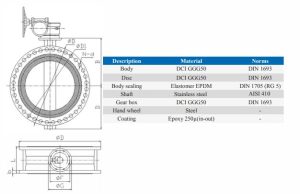

DOUBLE FLANGED

BUTTERFLY VALVE

Working pressure PN 16

Testing pressure PN 25

Face-to-face dimensions ISO 5752 (BS 5155)

Application: Potable water, Air conditioning systems, Chilled water

pumps, Fire and Irrigation systems.

(1) Alternatively, the shaft can be supplied in AISI 316 stainless steel or others, upon request.

(2) The epoxy resin coating is electro statically applied (inside and outside) with a minimum thickness of 250μ.

(3) The valve can operated as following:

a-With gear box.

b-With electric actuator.

d-With pneumatic actuator.

e-With hydraulic actuator.

Quality control: each valve is entirely tested according to ISO 5208.

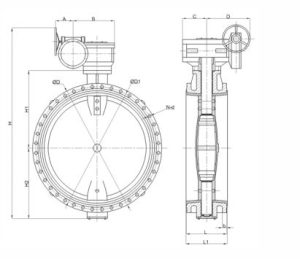

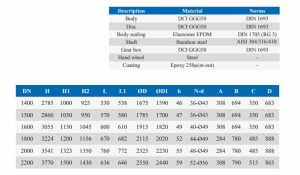

DOUBLE FLANGED

BUTTERFLY VALVE

Working pressure PN 16

Testing pressure PN 25

Face-to-face dimensions ISO 5752 (BS 5155)

Application: Potable water, Air conditioning systems, Chilled water

pumps, Fire and Irrigation systems

DOUBLE FLANGED BUTTERFLY VALVE

WITH METAL AISI 316 PLATED SEAT

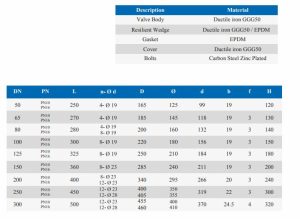

DOUBLE FLANGED

SOFT SEALING CHECK VALVE

Confirms to DIN 3352

Working pressure PN 10/16

Testing pressure PN 16/25

Flanges Comply with EN1092

Face to Face Dim. DIN3352-F5

Operating Tempreture 0°C to 71°C

Applications: Potable water, Sewage, Industrial waste water, Air

conditioning systems, Chilled water pumps, Fire and Irrigation

systems.

(1) Alternatively, can be supplied in elastomer NBR/SBR or others, upon request.

(2) The epoxy resin coating is electro statically applied (inside and outside) with a minimum thickness of 250μ.

Quality control: each valve is entirely tested according to ISO 5208.

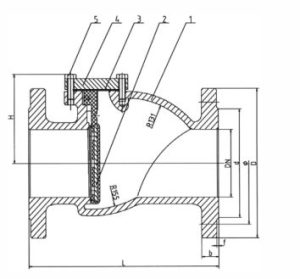

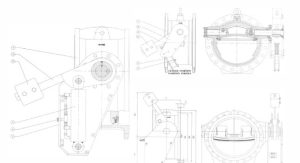

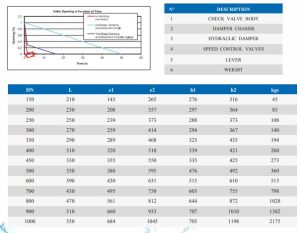

DOUBLE FLANGED

SWING CHECK VALVE

Working pressure: PN 10/16

Testing pressure: PN 16/25

Application:The valve is installed on the pipeline to prevent the

medium flowing back and efficiently restrain water hammer, so it has

function of protecting pipeline system.

Suitable for: Potable water, Sewage, Industrial waste water,

Air conditioning systems, Chilled water pumps, Fire and

Irrigation systems.

(1) Can be supplied with outside hydraulic damper or inside hydraulic damper or lever &counter Weight, upon

request.

(2) Alternatively, the shaft can be supplied in AISI 316 stainless steel or others, upon request.

(3) The epoxy resin coating is electro statically applied (inside and outside) with a minimum thickness of 250μ.

Quality control: each valve is entirely tested according to ISO 5208.

Closing characteristic example:

The two adjustment needle valves “3” determine the closure speed for two independant ranges:

– fast closure between 100% open and 30% open (example: 50%/s)

– fast closure between 30% open and 0% open (example: 2%/s)

(in the example, the influence of back flow has not been modelled)

Advantage: the valve closes in less time than a single-stage damped valve, but without a high-speed shock as

with a non- damped valve: the backflow is reduced whilst keeping a smooth operation.

Quality control: each valve is entirely tested according to ISO 5208.

TILTING TYPE CHECK VALVE

Working pressure: PN 10/16

Testing pressure: PN 16/25

DESIGN FEATURES :

-DIN 3202 F4: short body, small volume, light weight

-Swings freely controlled by flow. The disc opening depends on the flow velocity.

-Adjustable weight enables to adjust the opening behaviour

-Lever can be mounted two ways for horizontalor vertical application of check valve.

-Both metal to metal or resilient seating

-Maintenance free design.

Special order can be arranged for higher pressure range or sizes over 56″ or particular fluid.

TILTING TYPE CHECK VALVE WITH

HYDRAULIC DAMPER

Characteristics of the damped check valve same as

– Smooth closing of the disk, no slamming

Closing characteristic example

The two adjustment needle valves “3” determine the closure speed for two independant

ranges:

– fast closure between 100% open and 30% open (example: 50%/s)

– fast closure between 30% open and 0% open (example: 2%/s)

(in the example, the influence of back flow has not been modelled)

Advantage : the valve closes in less time than a single-stage damped valve, but without a

high-speed shock as with a non-damped valve: the backflow is reduced whilst keeping a

smooth operation.

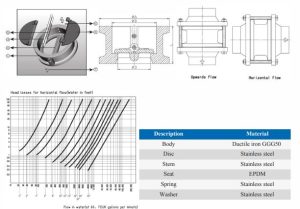

WAFER DUAL

PLATE CHECK VALVE

Design Working pressure PN 10/16

Design Testing pressure PN 16/25

Confirms to API 594

Operating Temp. 0°C to 82°C

Face to Face acc. EN558-1

Applications:Potable water, Industrial waste water, Air conditioning

systems, Chilled water pumps, Fire and Irrigation systems.

Features:Dual plate construction, Quick opening and closing action,

Spring loaded on the plate for quick closing, Opening angle

approaches 90°, Low head losses, Could be installed vertically

(only upwards flow) or horizontally, Soft seat with zero

percent leakage.

(1) Alternatively, can be supplied in elastomer NBR/SBR or others, upon request.

(2) Alternatively, the shaft can be supplied in AISI 316 stainless steel or others, upon request.

(3) The epoxy resin coating is electro statically applied (inside and outside) with a minimum thickness of 250μ.

Quality control: Each valve is entirely tested according to ISO 5208.

Inspection &Testing: Inspection and Testing must be done according to ISO5208:2008.

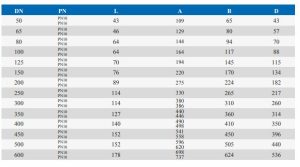

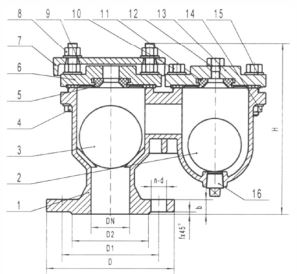

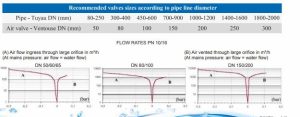

DOUBLE CHAMBER DOUBLE

BALL FLANGED END AIR VALVE

Working pressure PN 10/16

Testing pressure PN 16/25

Flange drilling BS 4504

Temperature <120°C

Applications: Potable water, Industrial waste water, Air conditioning

systems, Chilled water pumps, Fire and Irrigation systems.

DOUBLE CHAMBER AIR VALVE

Working pressure PN 10

Testing pressure PN 16

Operating Temp. -10°C to 120°C

Flange DIN 2501

DESIGN FEATURES :

– With integral isolation valve.

– Long trouble-free working life with polyethylene ball design.

– Spherical shape to improve reliability both in terms of precision

as well as reducing wear.

DOUBLE BALL AIR VALVE :

1. For bulk release of air filling of water mains.

2. For release of air trapped in water mains under working pressure.

RECOMMENDATIONS FOR THE LOCATION OF AIR RELEASE VALVE :

1. After pump discharge valves.

2. At local peaks in the system

3. At transition points in pipe slope.

4. Where along pipe sections of long uniform slope at every 500 m.

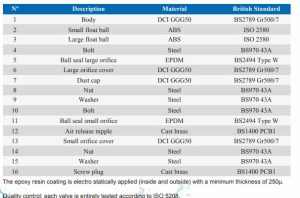

COMBINATION AIR VALVE

FOR SEWAGE

Description

The combination air valve combines an air & vacuum large orifice and an automatic small orifice in a single

body.

The valve is specially designed to operate with liquids carrying solid particules such as sewage and effluent.

The combination air valves discharges air (gases) during the filling or charging of the system, admits air to the

system while it is

being emptied of liquid and discharges accumulated air (gases) from the system while it is under pressure and

operating.

The valve’s unique design guarantees complete separation of the liquid from the sealing mechanism and provides optimum work

conditions.

Main features

– Working pressure range : 0,2 – 16 bars;

– The valve’s unique design prevents any contract between sewage and the sealing mechanism by

creating an air gap at the top of the valve. This air gap is guaranteed even under extrême conditions;

– The conical body shape designed to maintain the maximum distance between the liquidand the

sealing mechanism; so as to obtain minimim body length.

– Spring loaded joint between the stem and the upper float. Vibrations of the lower float will not

unseal the automatic valve. Release of air valve will occur only after enough air accumulates.

– The valve design, rolling seal mechanism : is less sensitive to pressure differentials than a direct

float seal. It accomplishes this by having a comparably large orifice for a wide pressure range (up to

16 bar);

– Funnel-shape lower body is designed to ensure that residues sewage matter will fall back into

system and be carried away by the main pipe;

– All inner metal parts made of stainless steel;

– 1″1/2 threaded drainage outlet enables removal of excess fluids;

– Preventing premature closing, the valve discharges air at high velocity;

– Maximum working temperature 90°C

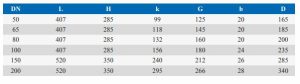

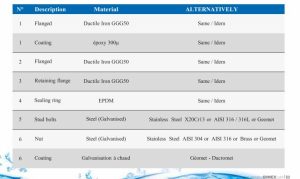

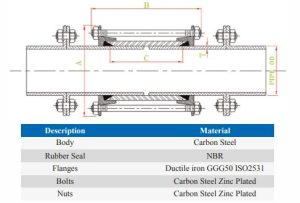

DISMANTLING JOINT

Working pressure PN 10/16

Testing pressure PN 16/25

Applications: Potable water, Sewage, Industrial waste water,

Air conditioning systems, Chilled water pumps, Fire and

Irrigation systems.

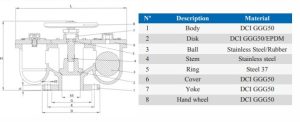

DOUBLE FLANGED

EXPANSION JOINT

Working pressure PN10/16

Testing pressure PN16/25

(1) The epoxy resin coating is electro statically applied (inside and outside) with a minimum thickness of 250μ.

(2) The joints are designed to allow deflection up to 7º.

Quality control: each joint is entirely tested according to ISO 5208

BALANCED FLOAT VALVE

Working pressure PN 10/16

Testing pressure PN 16/25

Face-to-face dimensions ISO 5752 (BS 5155)

PENSTOCK VALVE

(Circular or square opening)

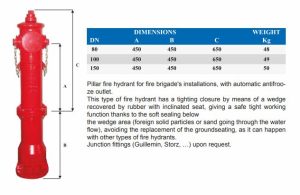

FIRE HYDRANT

Working pressure PN 16

Testing pressure PN 25

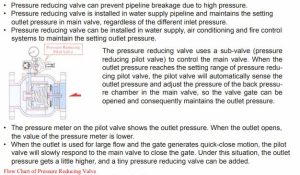

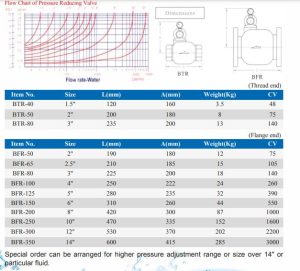

PRESSSURE REDUCING VALVE

Pressure Adjusting Range : 0.7 ~7Kgf/cm²

4 ~12 Kgf/cm²

(1 Kgf/cm² = 14.2 psi)

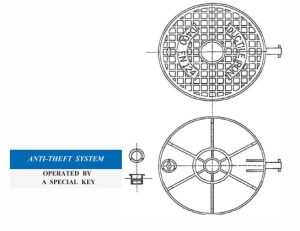

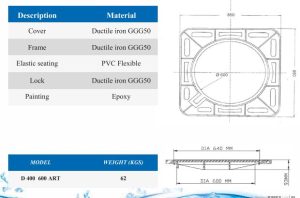

MANHOLE COVER D400/600 SQUARE

FRAME / ROUND COVER

ARTICULATED – WITH ANTI-THEFT

LOCKING SYSTEM

Breaking Charge: 400 KN