The main characteristics of MBBR Bio Filter to treat wastewater effectively

MBBR Bio Filter media is specially used in Integrated Fixed Film Activated Sludge System (IFAS) and Moving Bed Biofilm Reaction (MBBR) systems for water treatment.

Since MBBR media has the same density as water, it can be suspended in water and move freely in the reactor so that it mixes with the water. As the water in the reactor flows and aerates, it can remain fluidized. It acts as a carrier of microorganism activity in the MBBR system.

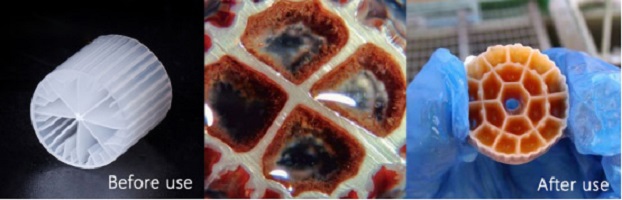

As the wastewater passes through the suspended filter media in the MBBR reactor, a biological film (biofilm) is gradually formed on the surface of the media. When the microbe adheres to the moving conveyor and forms a biofilm on the conveyor, it can purify the water.

The biological film is formed on the surface of MBBR bio media gradually.

Main features of MBBR Bio Filter

Design the geometric configuration according to fluid mechanics and enhance the surface adhesion ability

The specially designed geometric configuration has a huge effective specific surface area. The filling media is made of high-quality 100% pure HDPE polymer material and has strong impact resistance. Advanced surface treatment technology is more suitable for microbial adhesion growth, and provides a strong guarantee for fish pond water filtration and circulation.

The filler has a larger specific surface area and more adherent biomass

Its large specific surface area provides support for the attachment and growth of many microorganisms, and is suitable for the growth of various microorganisms, nitrifying bacteria, EM bacteria, filamentous bacteria, and other beneficial bacteria, and provides a solid foundation for the biological—removal of nitrogen and phosphorus from circulating water.

No support necessary, easy to liquefy, and energy-saving

Proper specific gravity puts the packing media in a suspended flow state, which reduces energy consumption and increases impact/cut on the bubble.

Very simple maintenance

General filter materials need regular cleaning and renewal. However, this new type of biological filler generally does not need cleaning and renewal after participating in the cycle. It can be used repeatedly and the service life is longer than 10 years.

In summary, the main characteristics of MBBR fluidized bed are as follows:

- The protected inner surface provides a good environment for microorganisms to attach and grow.

- Bubble cutting by many biological carriers improves the efficiency of dissolved oxygen.

- HDPE material can ensure a service life of more than 5-8 years

- Large protected area

- Water loving

- Different sizes and specifications meet different needs, durable and sturdy

- The vacuum size is adequate for water to pass through, and the biofilm can fall off on its own

- The use of non-toxic materials can ensure that the survival of microorganisms is not affected

How to install and get started

- There is no need to adjust the filling support in the aeration tank, which makes maintenance easy and less investment.

- Below is the suggested procedure for filling MBBR filter media into the aeration tank.

- While filling the MBBR filter media, workers should note if there is a buildup in the aeration tank. Once buildup occurs, grouting should be stopped. Usually, the filling process should be restarted the next day when there is no accumulation.

- While filling the MBBR filter media, intermittent aeration should be used. Ventilation can continue at night while reducing the amount of ventilation.

- After 24 hours of operation, feed water continuously for 2-3 hours and then continue the above aeration. After 48 hours of operation, observe film formation on the surface of the filter media. Increase water flow and extend water flow time. Check the dissolved oxygen status in the tank, it is best to keep the oxygen content at around 1.5-2.0mg/L.

- After 72 hours of operation, gradually increase the water flow to its designed condition.