Do you know the difference between soft seal gate valve and hard seal gate valve?

In this article, we explain the difference between a soft seal gate valve and a hard seal gate valve. The factors that determine which one to choose in different applications. At CareWater, we seek to provide a complete set of solutions for industrial valves.

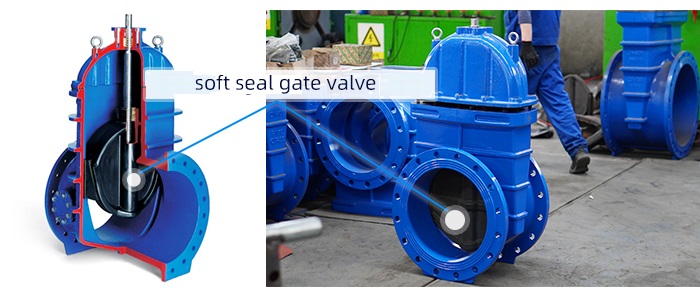

What is a soft seal gate valve?

Soft seal gate valve, industrial valve, soft seal gate valve opening, and closing member are the gate. The direction of movement of the gate is perpendicular to the direction of the fluid. The gate valve can only be fully open and fully closed, and can not be used for regulation and throttling. The gate has two sealing surfaces, the most commonly used mode gate valve two sealing surfaces form a wedge. The wedge angle varies with the valve parameters, nominal diameter DN50 ~ DN1200, the use of temperature: ≤ 200 ℃.

The principle of soft seal gate valve:

Wedge gate valve gate can be made into a whole, called steel gate; can also be made into a gate that can produce a slight deformation, to improve its craftsmanship, to compensate for the deviation of the sealing surface angle in the process of processing, this gate is called a flexible gate.

The soft seal gate valve is divided into two kinds soft seal gate valve and concealed soft seal gate valve. Usually, there are trapezoidal threads on the lift rod, and the rotary motion is changed into linear motion. That is, the operating torque is changed into operating thrust, by the nut in the middle of the gate plate and the guide groove on the valve body. When the valve is opened, the passage of fluid is completely open when the height of the gate lift is equal to 1:1 times the valve’s passage diameter.

But this position cannot be monitored during operation. In actual use, the top point of the valve stem is used as a marker, i.e., the position of open immobility, as its fully open position. To take into account the locking phenomenon due to temperature change, the valve is usually opened to the apex position and then reversed by 1/2-1 turn as the fully open position. Therefore, the full open position of the valve is determined by the position of the gate (i.e., stroke).

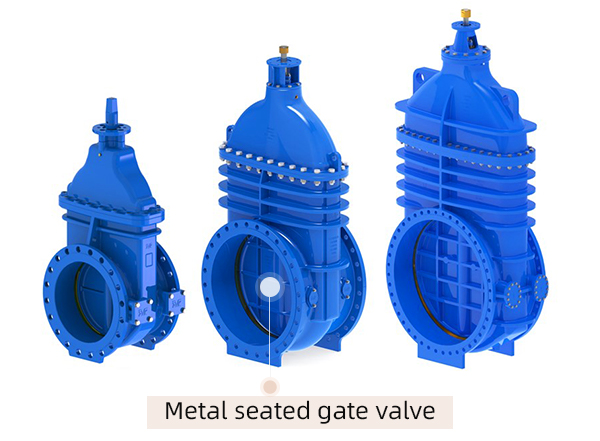

What is a hard seal gate valve?

The opening and closing part of the hard seal gate valve is the gate. The direction of movement of the gate is perpendicular to the direction of the fluid. The gate valve can only be fully open and fully closed, not for regulation and throttling. The gate has two sealing surfaces, the most commonly used mode gate valve with two sealing surfaces to form a wedge.

When the hard seal gate valve is closed, the sealing surface can only rely on the medium pressure to seal. That is, relying on the medium pressure will be the sealing surface of the gate to the other side of the valve seat to ensure the sealing surface sealing. Which is self-sealing. Most of the gate valves are forced to seal, that is, when the valve is closed, rely on external force to force the gate to the seat, to ensure the sealing surface of the seal.

Soft seal gate valves and hard seal gate valves are the two main categories in the gate valve series.

Hard seal and soft seal can sometimes make up for each other, and sometimes be independent of each other.

The difference between a soft seal gate valve and a hard seal gate valve is as follows:

Sealing material

Soft seal gate valve: sealing side of the metal material, the other side of the resilient non-metallic materials, called “soft seal”. This seal has good sealing performance, but not high-temperature resistance, is easy to wear, and has poor mechanical properties.

Hard seal gate valve: the two sides of the seal are made of metal or other hard materials, called “hard seal”. The sealing performance of this seal is poor but has high-temperature resistance, wear resistance, and good mechanical properties.

The structure mechanism

The hard seal gate valve is a metal-to-metal seal, the sealing ball and seat are metal. Processing accuracy and process is more difficult, generally used for high pressure, generally above 35MPa. A soft seal gate valve is a seal between metal and non-metal, such as nylon \ tetrafluoroethylene, manufacturing standards are the same.

Equipment selection

Soft and hard seal gate valve selection is mainly based on the process medium, temperature, and pressure. General media containing solid particles or abrasion or temperature higher than 200 degrees. It is best to use a hard seal. The diameter greater than 50 valve pressure difference is large, consider opening the valve torque. , when the torque is large, should be selected fixed hard seal ball valve, whether soft seal or hard seal, so its sealing grade can reach 6.

The use of conditions

Soft seal gate valves generally have a high seal, while hard seals can be high or low depending on the requirements. Soft seals need to be fireproof because the material of soft seals can leak at high temperatures. While hard seals do not have this problem; seals can usually be manufactured at very high pressures, but soft seals cannot. Soft seals cannot be used in some cases because of the flowing medium. Finally, hard seal valves are usually more expensive than soft seals. As for manufacturing, there is little difference between the two. The main difference is the valve seat, which is non-metallic for soft seals and metallic for hard seals.

With the continuous development of our industrial market, it is necessary to understand the difference between soft-seal gate valves and hard-seal gate valves, which may not only affect productivity but also greatly affect the economic benefits.

Structural characteristics.

The general gate valve used in the market for a long time is generally a leaky or rusty phenomenon. We at CareWater are working to provide flexible seal gate valves with high technology and valve manufacturing technology. To overcome the general gate valve’s poor sealing, rust, and other defects. The resilient seat seal gate valve uses the resilient gate plate to produce a trace of elastic deformation compensation effect to achieve a good sealing effect. The valve has a light switch, reliable sealing, and elastic memory. The valve has the advantages of light opening and closing, reliable sealing, elastic memory, and good service life.

Whether it is a soft seal gate valve or hard seal gate valve, in the process of use. We should pay attention to the following points:

- The handwheel, handle, and transmission mechanism are not allowed to be used for lifting, and collision is strictly prohibited.

- The double gate valve should be installed vertically (i.e., the stem is in a vertical position, handwheel at the top).

- The gate valve with the bypass valve should be opened before opening the bypass valve (to balance the pressure difference between the import and export and reduce the opening force).

- A gate valve with a transmission mechanism should be installed according to the product instruction manual.

- If the valve is frequently opened and closed, it should be lubricated at least once a month.