How to Choose a Stainless Steel Float Valve

The float valve is used as a mechanism or device for filling tanks and other containers with fluids. It is also referred to as a ball valves, as the float is typically shaped like a ball. It consists of a valve connected to a hollow and sealed float lever, and is installed near the top of the tank. The valve is connected to the pipe that brings the fluid, and it opens and closes with the lifting or lowering of the float lever. When it reaches a certain level, the mechanism causes the float lever to close the valve, cutting off the flow. Choosing a stainless steel float valve requires considering several factors, such as the style and material. Keep reading to learn how to choose the best float valves for your application!

What is a Float Valve and How Does It Work?

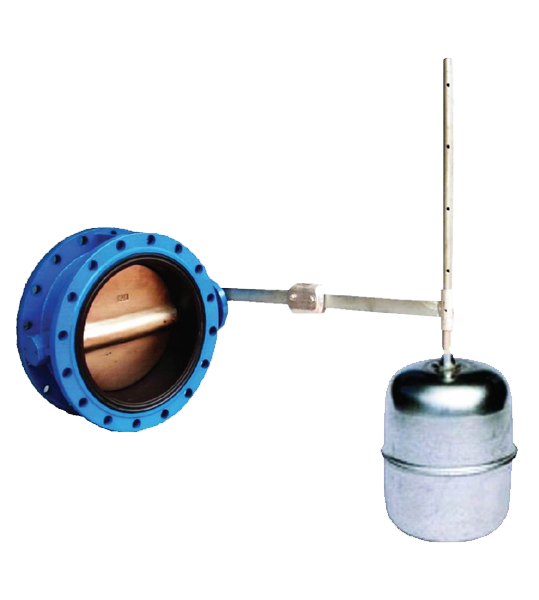

A float valve performs a simple function. It controls the flow of fluid from a supply source, such as a tank, and rises when the fluid level in the tank rises. The float valve consists of three parts: the float mechanism, the float valves, and the stem.

The valves are connected to the float mechanism through the stem, which acts as a lever to control the flow of fluid when the valve opens or closes. Generally, float valves are used in storage tanks to prevent fluid flow through the pipes, creating a leak-free seal when the stem rises. When the stem rises, the valve closes the flow.

The float mechanism usually contains air to give it buoyancy and ensure a tight seal. When the liquid leaves the tank, the float mechanism sinks with the liquid while the valves remain open until the float mechanism is raised again to a certain level, allowing the liquid to refill the tank. Float valves prevent overflow or overfilling of tanks by diverting the liquid instead of draining it. The valve and float mechanism move together when the tank is emptied and refilled, and they can operate mechanically or hydraulically.

Types of Float Valves

As a simple mechanical device that controls fluid levels in tanks or containers, float valves serve various purposes. They are often used in household water systems, including applications such as regulating pressure in hot water heaters’ cold water storage tanks. Smaller-sized float valves are also suitable for toilets to regulate water flow. Depending on the application, float valves operate under high-pressure conditions or low-pressure conditions. Here are some types of float valves commonly used:

High-Pressure Float Valves

High-pressure float valves work in excess steam systems with a single evaporator. These are vessels used for storing the liquid medium, with float valves installed to direct the discharged liquid from the condenser to the evaporator. It works as a steam trap and operates with a refrigerant such as ammonia or carbon dioxide.

High-Temperature Float Valve

Used in boilers, heat exchangers, boilers, and other high-temperature applications. It maintains fluid levels at an accurate level by using the float to operate the valve’s opening and closing.

Balanced Float Valves

Sometimes called balanced float valves, these valves help solve high operating torque. It consists of a single valve and a balanced piston. The balanced piston seal introduces a slight amount of friction, thus reducing operating torque. However it can provide significant benefits by reducing the resulting surges.