Valve Maintenance or Replacement: A Strategic Guide to Making the Right Decision

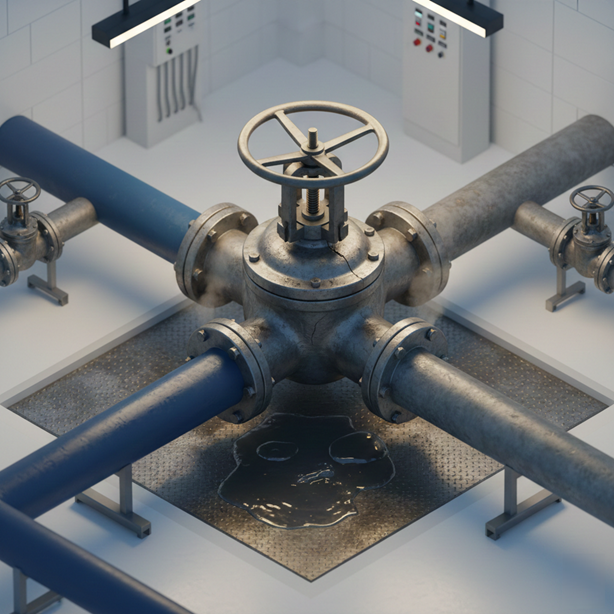

Valve maintenance or replacement refers to the essential practices and considerations for ensuring optimal performance and longevity of valves used in various applications. Valves are critical components in industrial, commercial, and residential systems, controlling the flow of fluids and gases, making their proper functioning essential for safe and efficient operation. It is worth noting that improper maintenance or failure to replace valves can lead to catastrophic failures, downtime, and significant financial losses, highlighting the importance of implementing effective maintenance strategies and understanding when replacement is necessary.

This topic encompasses various maintenance approaches, including reactive, preventive, predictive, and proactive strategies, each playing a crucial role in extending valve life. Preventive maintenance, which involves regular inspections and timely repairs, is more effective than reactive maintenance, which addresses problems only after a failure has occurred. Furthermore, advancements in predictive maintenance technologies allow for real-time monitoring of valve performance, facilitating early detection of potential issues and reducing the risk of unexpected failures.

Valve Types

Valves play a pivotal role in diverse applications, regulating the flow of fluids and gases in various systems. The types of valves used vary considerably depending on their function and application requirements. Below is an overview of the most common valve types, along with their characteristics and uses.

Maintenance Procedures

Regular valve maintenance is crucial to ensuring their efficiency and longevity. These procedures encompass a variety of practices that can be categorized as reactive, preventative, predictive, and proactive maintenance strategies. These maintenance procedures aim to prevent valve failures and optimize their performance through regular inspection, cleaning, lubrication, and repair.

Types of Maintenance

Reactive Maintenance

Reactive maintenance involves addressing valve problems only after they occur. This approach typically requires emergency repairs and can lead to prolonged downtime and increased costs due to unexpected failures. While reactive maintenance may mitigate catastrophic failures, it is often considered less effective than proactive strategies.

Preventive Maintenance

Preventive maintenance is essential for maximizing valve lifespan and performance. It includes regular inspections for leaks, corrosion, and wear, along with the prompt replacement of worn components. This maintenance helps minimize downtime and repair costs. A structured preventive maintenance program typically includes visual inspections, valve performance reviews, and periodic cleaning to extend service life and prevent emergencies. Regular cleaning is especially important for valves operating in harsh conditions, such as high temperatures or corrosive fluids.

Lubrication: Proper lubrication is essential for the moving parts of a valve, such as stems and bearings. Using appropriate lubricants reduces friction and wear, ensuring smooth operation. This maintenance includes tasks such as cleaning, lubrication, inspection, and repair, which collectively contribute to the efficient long-term operation of valves. Regular maintenance, typically performed monthly, quarterly, or annually, allows for the identification of potential problems before they worsen. However, traditional practices may have limitations and often fail to address all issues.

Read also: The Importance of Preventive Maintenance for Water Treatment Plants

Types of Maintenance Methods

Different maintenance strategies can significantly impact valve performance. Reactive maintenance, which is only performed after equipment failure, can lead to costly downtime and ineffective repairs. In contrast, proactive methods, such as predictive maintenance, help anticipate and prevent failures before they occur, reducing the risk of unexpected breakdowns and extending valve life.

Physical and Environmental Factors

The valve material plays a vital role in its maintenance needs and service life. For example, brass valves are known for their durability, while valves made of polymer materials may be damaged in high temperatures or corrosive environments. Understanding the specific conditions a valve is exposed to—such as temperature ranges, pressure levels, and the nature of the fluid flowing through it—helps in selecting the appropriate valve and determining its maintenance requirements.

Operational Performance and Failure Indicators

Monitoring operational performance is crucial in determining maintenance needs. Common indicators of valve problems include leaks, poor process control, and valve stem stiffness. For example, leaks may indicate corrosion or mineral buildup, while poor process control may indicate that the valve is not achieving the required flow rate due to a malfunction. Early detection of these indicators can help prevent further damage and extend valve life.

Professional Expertise and Repair Complexity

In some cases, the expertise of valve manufacturers or specialized service providers is essential for performing complex repairs or calibration tasks. Hiring specialists ensures that valves are maintained according to the latest standards and techniques, which can be particularly beneficial in environments where safety is a top priority.

Signs of Valve Failure

Valves play a crucial role in various systems, and their failure can lead to significant operational problems. Early recognition of valve failure signs can help prevent serious damage and costly repairs.

Vibrations and Noise

Unusual vibrations and noises are among the first warning signs of valve failure, especially with check valves. When valves begin to fail, they may vibrate excessively, and in some cases, parts may detach from the valve body. This problem is often accompanied by a phenomenon known as “water hammer,” where the disc strikes the valve seat, potentially leading to pipe rupture if not addressed immediately.

Leakage

Valves that begin to leak are another clear indicator of a malfunction. Leaks can occur due to various factors, such as damage to the valve seat or disc, or the introduction of contaminants into the pipeline. Additionally, leaks can result from unreliable seals or improperly installed fittings, which can exacerbate the problem if left unaddressed.

Stuck Mechanisms

Stuck valves are those that become stuck in a particular position, often due to a buildup of deposits that obstruct the valve disc and body cavity. This obstruction can prevent the valve from functioning correctly, leading to backflow or other operational problems. Regular inspection is essential to prevent deposit buildup and maintain smooth operation.

Excessive Corrosion and Rust

Over time, valves can become corroded and rusted, especially when exposed to extreme temperatures or corrosive materials. Regular visual inspections help identify early signs of damage, such as rust or pitting on valve surfaces. If rust is detected, it is essential to address the problem immediately to prevent further damage and potential valve failure.

Replacement Options

When servicing or upgrading valves in industrial applications, several replacement options are available, depending on the specific circumstances and the condition of the existing valve.

Total Valve Replacement

In cases of severe damage or failure, a total valve replacement may be necessary. This is typically required when the valve is so badly corroded that repair is impossible, often due to severe corrosion or contamination that cannot be effectively cleaned. For example, in a heart valve replacement procedure, the old valve is removed and replaced with a new mechanical or biological valve. This procedure is crucial for restoring valve function when repair is not possible. Complete valve replacement can also be applied in industrial applications where old or faulty valves can negatively impact safety and operational efficiency.

Replacing O-rings

In cases of valve leakage, replacing the O-rings is often a practical solution. O-rings are commonly used for this purpose, and regular replacement is essential to maintain proper sealing. This method is less invasive than complete valve replacement and is a cost-effective way to extend valve life.

Minimally Invasive Surgery Options

Minimally invasive techniques, such as transcatheter aortic valve replacement (TAVR), are emerging as alternatives in both medical and industrial settings. These techniques reduce recovery time and associated risks compared to traditional surgery. In industrial applications, similar strategies can be used to perform repairs or replacements with minimal disruption to operations.

Factors Influencing Replacement Decisions

Several factors determine when replacement is the optimal choice. Severe corrosion, significant contamination, or the inability to repair critical components are key indicators that replacement is necessary rather than maintenance. Furthermore, valve installation and operation standards can significantly impact a valve’s lifespan and effectiveness; improper installation can lead to premature failure.

Cost Considerations

Replacement costs vary considerably depending on the valve type and the complexity of its installation. For example, a valve repair kit might cost as little as $250, while a complete valve replacement could be much more expensive and time-consuming. Therefore, understanding a valve’s lifecycle and maintenance requirements is essential for making informed decisions about replacement versus routine maintenance.

Read also: The Role of Maintenance in Reducing Future Repair Costs in Water Treatment Plants