Valve Failures in Water Treatment Plants

Valve failures in water treatment plants are a major concern, as they can negatively impact the efficiency and safety of water purification processes. These vital components regulate water flow and pressure, and their failure can lead to reduced operational efficiency, safety hazards, and non-compliance with regulations. Common malfunctions, such as leaks, cavitation, and irregular operation, not only disrupt the treatment process but also pose public health risks by potentially introducing contaminants into the water supply.

Addressing valve failures is crucial due to their potential economic impact, which can include increased maintenance costs, higher energy consumption, and hefty fines for environmental violations. As regulatory standards evolve to address emerging contaminants, water treatment plants face increasing pressure to ensure the reliability and effectiveness of their systems.

Understanding the Causes and Consequences of Valve Failures

The causes of valve failures range from mechanical malfunctions and control system problems to environmental factors and improper installation. Proactive maintenance strategies, such as predictive maintenance and periodic inspections, are essential for identifying potential problems early and mitigating their impact on water treatment operations.

In short, understanding the causes and consequences of valve failures is critical to maintaining the safety of water treatment plants. Effective management and maintenance practices not only improve operational efficiency but also contribute to protecting public health and complying with environmental regulations, underscoring the pivotal role of valves in the water treatment process.

Common Valve Failures

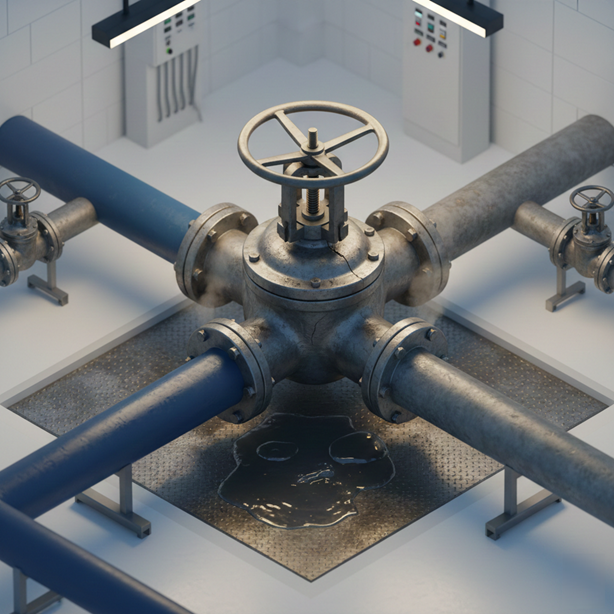

Valves are essential components in water treatment plants, and their failure can lead to a significant decrease in operational efficiency and safety concerns. Below are some of the most common valve problems in these plants.

Leakage

Leakage is one of the most common valve problems, often resulting from worn sealing rings, damaged valve seats, or improper installation. Over time, sealing rings and packing materials can deteriorate, leading to leaks around the valve stem or seat. These leaks not only waste resources but can also pose safety risks if the leaking fluid is hazardous. Addressing leaks early by replacing or adjusting sealing rings is crucial to preventing larger problems such as product loss and non-compliance with environmental standards.

Cavitation

Cavitation occurs when sudden pressure changes cause vapor bubbles in the fluid, which can burst and damage valve components. This phenomenon is particularly problematic in the water treatment and power generation industries, as it leads to surface corrosion, vibrations, and reduced efficiency. Regular valve maintenance can mitigate the risks associated with cavitation.

Adhesion or Immersion

Adhesion or smudging of valve components can occur when internal parts are corroded, damaged, or clogged with deposits. This malfunction makes it difficult to regulate flow or fully open and close the valve, negatively impacting the efficiency of the water treatment process. Regular maintenance and inspection can help prevent these problems.

Irregular Operation

Irregular operation is characterized by irregular opening and closing or fluctuating flow control, often associated with actuator malfunctions or control system failures. These problems can lead to unstable water flow, negatively impacting treatment processes and potentially water quality. Detecting signs of irregular operation is crucial for timely intervention.

Valve Seat Corrosion

Valve seat corrosion can significantly impair valve performance. Over time, material deterioration due to corrosion or erosion can weaken the valve’s ability to maintain a tight seal, leading to leaks and reduced operational efficiency. Regular inspections and proactive maintenance strategies are essential to extend valve seat life and ensure optimal performance.

Read also: The Importance of Valve Maintenance in Treatment Plants as a Cornerstone of Operational Efficiency

Causes of Valve Failures

Valve failures in water treatment plants can arise from multiple factors that negatively affect their performance, leading to reduced efficiency and safety hazards. Understanding these causes is essential for effective maintenance and safe operation.

Mechanical Failures

Mechanical failures are among the most common causes of valve failure. Problems such as valve stem gasket leakage occur when the sealant deteriorates, allowing process fluid to leak out, which can pose environmental hazards.

In addition, actuator failures can prevent valves from responding correctly to control signals. Ripped air diaphragms or broken springs are common problems. Seat wear, especially in valves handling abrasive fluids, can also reduce a valve’s ability to prevent leakage, leading to increased leakage rates and decreased process efficiency.

Control System Issues

Control system failures often complicate valve troubleshooting. Malfunctioning positioners, which translate control signals into precise valve movements, represent a major pattern of failure. These positioners may be affected by electromagnetic interference or moisture ingress, resulting in incorrect valve positioning. Furthermore, signal calibration problems between the control system and the valve can cause unintended valve movements, while signal interruptions can activate default safety modes, disrupting production processes.

Environmental and Material Compatibility Issues

Valves may also fail due to environmental conditions or material incompatibility. Valves exposed to harsh environments, such as those handling corrosive materials or subjected to thermal cycles, are more prone to corrosion and failure. Regular inspections for signs of corrosion or material deterioration can mitigate these risks and extend valve life.

Installation and Assembly Errors

Improper assembly and installation are common causes of valve failure. Poor installation can lead to misalignments that mimic valve failure, complicating diagnosis and repair. Following best practices for valve assembly is crucial to ensuring proper performance and preventing premature failure.

Operational Factors

Operational factors, such as pressure fluctuations or flow irregularities, often indicate underlying valve problems. Blockages or corrosion can disrupt normal operations, while leaks resulting from worn seals or damaged valve seats can waste resources and pose safety hazards. Regular maintenance, including visual inspections and lubrication of moving parts, can help address these problems before they lead to serious failures.

Impact on Water Treatment Operations

Valve failures can have significant repercussions on water treatment operations, affecting the efficiency and safety of water purification systems. Pump failures are among the most serious of these impacts. Faulty valves can cause water flow interruptions and disrupt the entire treatment process. These interruptions can lead to the leakage of untreated or partially treated water, violating environmental regulations and posing a risk to public health standards. The financial consequences of pump failures related to valves can be substantial, including repair costs, lost productivity, increased energy consumption, and potential penalties for non-compliance with regulations.