Types of Valves in Greywater Treatment Plants

Greywater treatment plants are essential facilities designed to treat wastewater generated from domestic activities such as washing, showering, and cleaning, which typically contains pollutants requiring careful management. Key components of these systems include various types of valves used to regulate water flow and direction during the treatment process. Selecting and maintaining the appropriate valves is vital to ensuring efficient operation and compliance with environmental standards, making the topic of valves in greywater treatment a crucial aspect of sustainable water management practices.

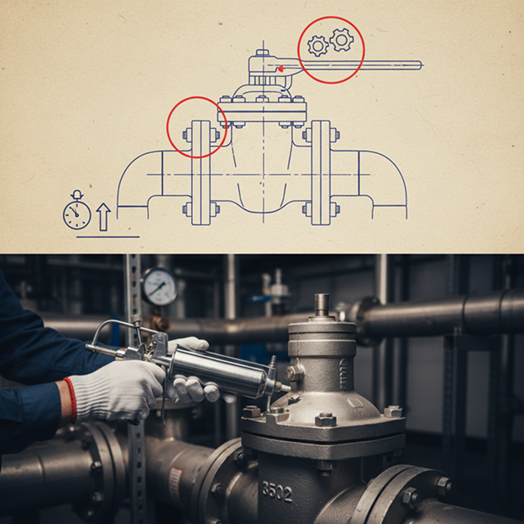

The main types of valves used in greywater treatment include ball valves, butterfly valves, gate valves, and non-return valves. Each valve type performs specific functions based on its operational characteristics. For example, ball valves allow for rapid flow control and are suitable for high-pressure systems, while gate valves are primarily used for on/off operation. Non-return valves are essential to prevent backflow, which can negatively impact system integrity, while butterfly valves are preferred for their lightweight design and quick operation. Understanding these differences is crucial for optimizing the treatment process and ensuring the sustainability of the systems involved.

Furthermore, the selection of appropriate valve materials is influenced by several factors, including mechanical properties, environmental conditions, and the specific characteristics of the greywater. Materials must be resistant to corrosion and wear, given the potentially harsh properties of contaminants present in greywater. Economic considerations, such as life-cycle costs and compliance with industry standards, also play a significant role in the decision-making process when selecting valves for these systems.

Overview of Valves

Valves play a critical role in greywater treatment plants by regulating the flow and direction of water through various systems. Valves are essential components for ensuring the efficient management of greywater, which typically contains contaminants and chemicals requiring careful handling.

Types of Valves

In greywater treatment plants, various types of valves are used to control water flow and optimize the treatment process. The most common valves include ball valves, butterfly valves, gate valves, and non-return valves, each with distinct functions based on its design and operating characteristics.

Gate Valves

Gate valves are primarily designed for on/off operation, not for flow regulation. These valves utilize a gate or wedge mechanism that rises to allow water to pass through when opened. They are easy to operate and maintain, making them suitable for many applications in greywater treatment systems. However, they do not offer flow control, which can be a limitation in some cases.

Read also: Gate Valve Maintenance in Water Treatment Plants

Non-Return Valves

Non-return valves, or check valves, play a crucial role in preventing backflow in piping systems. These valves rely on forward water pressure to remain open and automatically close in case of backflow. This feature is essential for maintaining the integrity of water systems, ensuring smooth operation, and preventing problems caused by backflow.

Non-return valves are critical in greywater treatment to prevent contamination and maintain efficient flow direction. Together, these different types of valves enhance the efficiency and reliability of greywater treatment processes, contributing to sustainable water management practices. The advantages and disadvantages of each valve type must be considered when designing and operating greywater treatment systems to ensure optimal performance and safety.

Butterfly Valves

Butterfly valves are widely used in greywater treatment systems due to their lightweight and ease of operation. They consist of a circular disc that rotates 90 degrees inside the pipe to regulate flow. This type of valve is preferred for its rapid opening and closing, which can be operated manually or pneumatically, providing effective water flow control. Despite their effectiveness in many applications, butterfly valves are not recommended for high-pressure systems. Their compact design allows for installation in confined spaces, making them versatile for various applications.

See also: Pneumatic Butterfly Valve Maintenance Guide

Ball Valves

Ball valves feature a spherical disc that controls flow through a quarter-turn rotation. This design allows for easy opening and closing, making them ideal for applications requiring rapid flow control. They are particularly well-suited to high-pressure conditions and are also durable, making them commonly used in water piping systems, including those in greywater treatment plants. However, their complexity can make cleaning them more difficult, especially in the food industry.

Importance of Valve Selection

Selecting the right valve for greywater treatment equipment is crucial for system efficiency and reliability. Factors such as valve size, material compatibility, and specific system requirements must be considered to ensure optimal performance. Valves must withstand the unique challenges posed by greywater, including the presence of contaminants, necessitating the use of materials with good corrosion resistance. Proper valve maintenance is equally important, as it helps prevent failures and ensures the longevity of the treatment system.

Valve Selection Criteria

Selecting the right valves for greywater treatment plants is critical to ensuring efficient operation and system longevity. The material selection process is influenced by a variety of factors, including mechanical properties, environmental conditions, fluid characteristics, and regulatory compliance.

Factors Affecting Valve Selection

Mechanical Properties

The mechanical properties of valve materials are crucial in determining their suitability for specific applications. Key attributes such as tensile strength, ductility, and stress resistance play a significant role in valve performance under operating pressure. For example, stainless steel is often preferred due to its high tensile strength and excellent corrosion resistance, making it ideal for handling the corrosive nature of greywater. In contrast, materials like cast iron may be unsuitable for high-pressure applications due to their brittleness and tendency to crack.

Environmental Conditions

Operating conditions within greywater treatment plants vary considerably. Extreme temperatures, both high and low, can significantly impact material behavior. High temperatures can soften metals, while low temperatures can make some materials brittle. Therefore, selecting materials that can withstand the specific temperature ranges encountered during the treatment process is essential.

Fluid Properties

The nature of greywater, including its viscosity, corrosiveness, and the presence of suspended particles, greatly influences the selection of valve materials. Valves must be able to resist the corrosion and wear caused by these properties. For example, valves handling highly abrasive or corrosive greywater may require materials with enhanced corrosion resistance and high durability. Such as specialized alloys or protective coatings.

Economic Considerations

Economic factors play a vital role in valve selection. Organizations must evaluate not only the initial costs of valves but also the long-term expenses related to maintenance, replacement frequency, and overall performance throughout the valve’s lifecycle. Compliance with industry standards, such as those established by ASTM and API, further influences the economic decision-making process. Ensuring operational safety and reliability.