Types of Chemical Mixers in Water Treatment Applications

Chemical mixers are essential components in the water treatment industry, facilitating the efficient mixing and dispersion of various chemicals necessary for improving water quality. Their importance lies in their pivotal role in processes such as coagulation, flocculation, and chemical dosing, which are indispensable for ensuring safe drinking water. Mixers come in various types, including stationary mixers, paddle mixers, high-shear mixers, drum mixers, and agitation mixers. Each type performs specific functions based on the physical and chemical properties of the materials being treated, as well as the operational requirements of the treatment plant.

Stationary mixers, known for their energy efficiency and low maintenance requirements, are widely used in continuous processes. Paddle mixers offer flexibility and the ability to handle delicate materials gently. High-shear mixers are distinguished by their superior ability to form emulsions and rapidly disperse solids, thus improving the efficiency of chemical production in water treatment. In contrast, cylindrical mixers are used in large-scale operations by mixing free-flowing materials within rotating cylinders, while motorized mixers are capable of handling viscous materials through axial and radial flow patterns.

Types of Chemical Mixers

Chemical mixers play a pivotal role in the water treatment industry, ensuring efficient mixing of chemicals and homogeneous distribution of materials. Different types of mixers are used depending on the specific requirements of the processes involved.

Stationary Mixers

Stationary mixers operate without moving parts, relying on strategically placed internal elements to mix materials as they flow through pipes. This design improves energy efficiency and reduces maintenance requirements, making them ideal for continuous operations in the water treatment sector. Stationary mixers are often used for mixing chemicals, dispersing gases in liquids, and blending immiscible liquids to form emulsions. Their ability to ensure homogeneous mixing makes them the preferred choice in applications requiring precise and reliable results.

Paddle-Blade Mixers

Paddle-blade mixers are widely used in water treatment applications due to their versatility and gentle handling of materials. Their paddle blades scoop, lift, and agitate materials, allowing for even distribution of both solid and liquid mixtures. This design is particularly useful for handling materials with varying consistencies, such as viscous substances and mineral powders. Paddle mixers are highly effective at mixing delicate materials without compromising their integrity, making them suitable for applications requiring product quality control.

High-Shear Mixers

High-shear mixers utilize a rotating-stationary mechanism to generate powerful shear forces, effectively breaking down particles and distributing them evenly throughout the mixture. These mixers are especially useful for emulsifying immiscible liquids or dissolving solids in liquids, making them indispensable for producing high-quality chemical water treatment mixtures. Their rapid and precise mixing capabilities significantly reduce processing time, improving production efficiency.

Drum Mixers

Drum mixers are designed to mix free-flowing materials within a rotating drum, making them suitable for a wide range of applications in the water treatment industry. They are effective in mixing various building materials and chemicals used in water treatment processes. Their robust design enables them to handle demanding applications while maintaining operational efficiency.

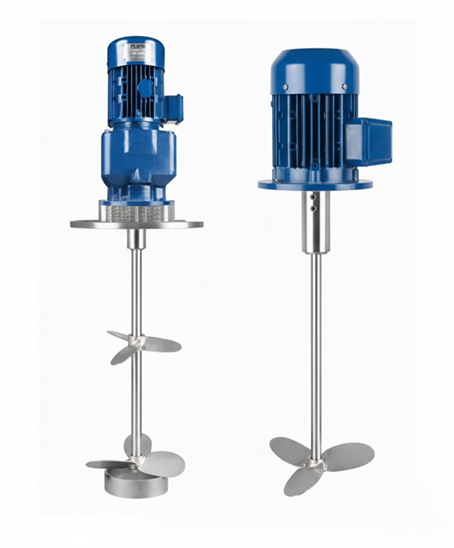

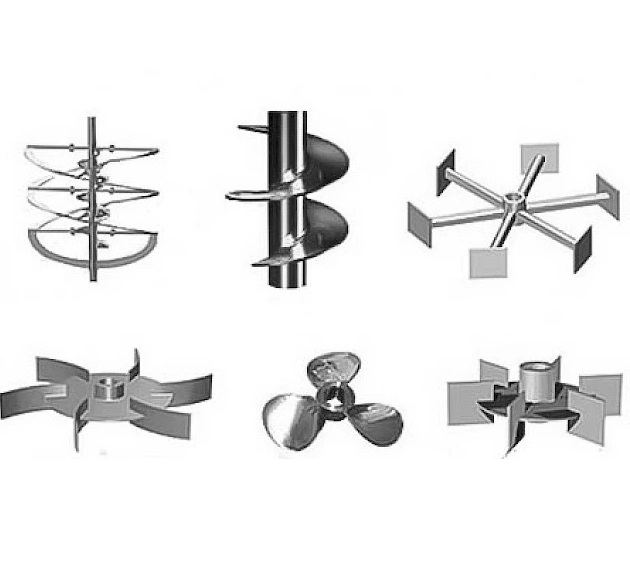

Driven Mixers

Driven mixers are classified into two types: axial and radial, depending on the direction of the impeller blades. Axial mixers direct the flow along the impeller axis, making them ideal for vertical rotation. Radial mixers create a flow perpendicular to the impeller axis, making them suitable for horizontal movement. These mixers are highly efficient. Chemical mixers are used with high efficiency in processing high-viscosity materials, which are common in water treatment applications.

Read also: How is a Water Treatment Plant a Long-Term Investment?

Applications in Water Treatment

Chemical mixers play a pivotal role in the water treatment industry, facilitating the efficient mixing of various materials to ensure optimal treatment results. Their applications can be categorized into several key processes.

Coagulation and Flocculation

Coagulation and flocculation are essential processes for treating water turbidity and improving water quality. During coagulation, chemical mixers help distribute coagulants evenly throughout the water, promoting charge neutralization of suspended particles. This is followed by flocculation, where mixers facilitate the aggregation of these particles into larger clumps. That can then be easily separated from the water. The efficiency of these processes depends heavily on the correct mixing of chemicals to maximize contact and interaction with the suspended particles.

Mixing for Chemical Dosing Systems

Mixing in chemical dosing systems is one of the primary applications of chemical mixers. These systems are designed to precisely titrate and mix chemicals in water for treatment purposes, such as adding coagulants, disinfectants, and pH adjusters. Automated chemical dosing systems utilize mixers to ensure consistent and accurate dosing, reducing the risk of over- or under-use of chemicals and thus improving compliance with regulatory standards and overall water quality.

Sludge Mixing and Aeration

Chemical mixers are also used in sludge mixing and aeration processes. In wastewater treatment, effective mixing is essential to ensure the homogeneous distribution of chemicals and promote sedimentation.

Solids. This is particularly important in processes involving sedimentation, where thorough sludge mixing improves separation and results in higher-quality treated water. Additionally, mixers aid aeration by enhancing oxygen transport in biological treatment processes. Supporting the growth of microorganisms essential for the decomposition of organic matter.

Improvement and Integration

As the water treatment industry moves towards more integrated and efficient processes, chemical mixers are increasingly being incorporated into automated systems that leverage advanced modeling and simulation tools. This allows for immediate adjustments and improvements based on water composition and treatment requirements. Enhancing the efficiency and effectiveness of water treatment operations.

Design Considerations

When selecting a chemical mixer for use in the water treatment industry, several key design considerations must be taken into account to ensure optimal performance and compliance with industry standards.

Environmental Factors

The operating environment is a critical factor in mixer design. Factors such as temperature and exposure to corrosive substances significantly affect the materials and fillers used in mixers, which can ultimately impact equipment lifespan and product quality. High-quality materials, such as stainless steel, are essential for ensuring durability under harsh conditions, especially when mixing abrasive or corrosive materials.

Material Properties

Understanding the properties of the materials to be mixed is crucial. Viscosity and density are critical criteria that influence mixer selection. For example, high-viscosity materials typically require specialized mixers, such as drill mixers, while low-viscosity liquids can be efficiently mixed using paddle mixers. Additionally, the compatibility of the mixer’s construction materials with the chemicals being mixed is critical. Corrosive materials require mixers made of materials resistant to chemical reactions.

Process Requirements

Specific mixing process requirements—such as batch size, mixing speed, and desired outcome—play a significant role in selecting the appropriate mixer. For example, large tanks may require mixers with powerful blades or paddles to ensure thorough mixing of heavy materials. Furthermore, considerations related to the mixing process, including the need for automated control systems to regulate parameters such as temperature and pH, enhance the overall efficiency of the operation.

Standard Compliance

Adherence to safety and quality standards is essential in the water treatment industry. It is crucial to evaluate mixer designs against quality certifications such as ISO 9001 or US Food and Drug Administration (FDA) standards. Which ensures that equipment meets the required safety and quality standards. This adherence is particularly important in industries where the quality of the final product is subject to strict regulatory standards, such as pharmaceuticals and food production.

Maintenance and Longevity

Designing mixers with ease of maintenance in mind can extend their operational lifespan and improve their reliability. Implementing a regular maintenance schedule, along with using easy-to-clean designs, can prevent the buildup of materials that can negatively impact performance. Features that reduce wear and facilitate quick repairs are also beneficial, minimizing downtime and associated costs. By carefully considering these design aspects, water treatment professionals can select mixers that not only improve operational efficiency but also ensure compliance with environmental and safety standards.

Advantages and Disadvantages

In the water treatment industry, the selection of chemical mixers is critical for process optimization. Each type of mixer has its own set of advantages and disadvantages that affect operational efficiency and cost-effectiveness.

Advantages of Chemical Mixers

One of the most important advantages of chemical mixers is their ability to efficiently process large quantities of materials. Continuous mixers, for example, are particularly suitable for large-scale production processes. They offer low energy consumption while maintaining high throughput. Batch mixers, on the other hand, are versatile and adaptable to various viscosities and mixing requirements. This ensures thorough mixing for processes demanding high precision. The design of batch mixers also facilitates maintenance, making them an attractive option for many facilities.

Furthermore, the right mixer can improve product quality by ensuring homogeneous mixing of materials. This is crucial in applications requiring strict adherence to hygiene and safety regulations. Such as in the pharmaceutical and food industries. As technology advances, newer mixer models are being developed, offering improved efficiency and versatility. That can lead to further savings in operating costs.

Disadvantages of Chemical Mixers

Despite their advantages, chemical mixers also present several challenges. A major drawback is the high initial cost associated with advanced mixing systems, particularly continuous mixers, which may deter smaller companies from investing in these technologies. Furthermore, maintaining consistent mixing quality can be difficult. Issues such as mixture heterogeneity and equipment wear can lead to inconsistent results and increased operating costs if left unaddressed. Additionally, some mixers, such as dry feed systems, can generate dust and require careful operator attention, resulting in higher maintenance and operating costs. The complexity of some advanced mixers necessitates specialized technical personnel for proper operation and maintenance. That can be a barrier for organizations lacking the necessary in-house expertise. Ultimately, careful consideration of these factors is crucial for selecting the most suitable mixer for various water treatment applications.