The Importance of Raw Water Pumps in Various Applications

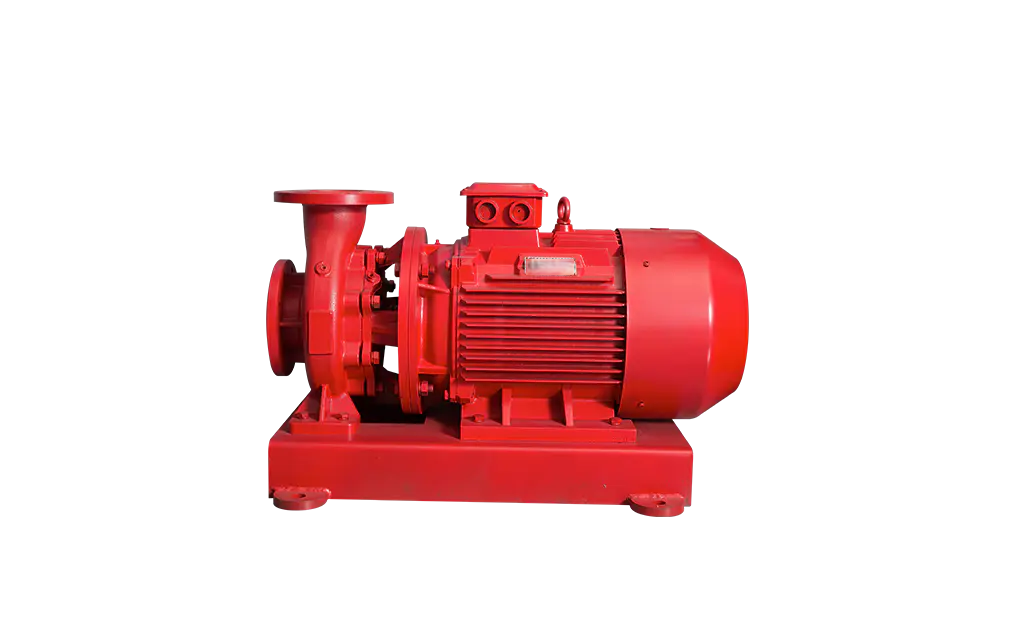

Raw water pumps are essential components in water treatment systems, designed to maintain operational efficiency and ensure a constant water supply for various processes. These pumps extract water from natural sources such as rivers, lakes, and reservoirs, and transport it to treatment plants. Key features of efficient raw water pumps include a robust impeller design, powerful motor capabilities, and specialized sealing systems to prevent leaks during operation.

In many cases, raw water pumps operate continuously to manage large volumes of water, highlighting the importance of energy efficiency and reliable performance. The operational efficiency of these pumps directly impacts the overall productivity of a water treatment plant.

Regular maintenance, including inspection of seals and bearings, is essential to prevent operational failures and leaks, thus maintaining the efficiency of the water supply system.

Backwash Pumps

Backwash pumps play a vital role in maintaining water quality during the treatment process. They facilitate the backwashing process, which involves reversing the flow of water through the filter media to remove accumulated impurities.

This process is crucial for preventing blockages at pump inlets and ensuring optimal flow rates. Backwash pumps are often equipped with their own motors and operate independently from other pumping systems, allowing for effective filter cleanliness without disrupting the overall water flow.

Backwash pumps operate on a strategic timing system, automatically starting based on sediment buildup on suction screens or filters. By efficiently managing this process, backwash pumps help maintain the effectiveness of filtration systems, ensuring a continuous supply of clean water while minimizing the potential environmental impacts of untreated or poorly treated water.

This article will discuss the uses of raw water feed and backwash pumps.

Benefits of Using Raw Water Pumps

Using raw water in cooling and pumping systems offers numerous economic and environmental advantages. These benefits can be categorized into several key areas, including efficiency, cost reduction, and sustainability.

Economic Benefits

Using raw water significantly reduces the operating costs associated with water treatment. By reducing the need for continuous extraction and treatment of large quantities of raw water from natural sources, industries can achieve significant savings in water purchase and treatment costs.

Furthermore, when water is reused within an industrial facility, treatment processes often require less intensive processing compared to treating fresh raw water, resulting in savings in chemicals and energy consumption.

Environmental Benefits

The use of raw water contributes positively to environmental sustainability by reducing the demand for fresh water resources and minimizing waste generation. Effective water management practices, such as reducing water consumption, reusing, and recycling, not only conserve resources but also help ensure compliance with environmental regulations, mitigating the risks associated with under- or overuse of chemicals in water treatment processes.

In addition, integrating social and environmental impact assessments into water management strategies helps industries make informed decisions that benefit their operations and the environment.

Operational Efficiency

Investing in technologies for monitoring pump systems and water treatment processes enhances reliability and operational efficiency. These monitoring systems help reduce unplanned downtime and repair costs by ensuring continuous compliance with environmental regulations and improving the overall quality of plant operations.

Clean and well-managed water systems contribute to improved energy efficiency, as high-quality water prevents the buildup of scale and deposits in equipment, extending machine lifespan and reducing maintenance needs.

Contributing to Food Safety

In sectors such as food and beverage manufacturing, water quality is critical to maintaining safety standards. Proper water treatment and reuse can enhance operational efficiency while ensuring that water used in cleaning and sanitizing processes is free of harmful microorganisms. This focus on water quality not only supports compliance with food safety regulations but also provides protection against potential foodborne illness outbreaks.

Challenges of Raw Water Feed Pump Implementation

The implementation of raw water feed pumps and backwashing systems faces several significant challenges that must be addressed to promote efficiency and sustainability in water management.

Affordability and Accessibility

The affordability of sustainable water pumping technologies is a major obstacle. Many communities, particularly in developing regions, have limited financial resources to invest in advanced pumping systems. To facilitate the widespread adoption of these technologies, it is essential that governments, NGOs, and the private sector promote and support sustainable solutions. Furthermore, raising technological awareness among users can lead to more informed decisions regarding the adoption of efficient pumping systems.

Operational Efficiency and Maintenance

Monitoring and maintaining optimal performance levels of pumping systems also presents challenges. Pumps operating outside their optimal efficiency point (BEP) are subject to accelerated wear and tear, resulting in costly repairs and a shortened service life.

The absence of effective monitoring systems can lead to unplanned downtime and increased operating costs. Implementing proactive pump condition monitoring can mitigate these issues, allowing maintenance teams to address potential failures before they escalate, thus maximizing return on investment.

Environmental Impact

Environmental concerns also complicate the use of raw water feed pumps and backwash pumps. The lifecycle emissions of these systems can be substantial, especially if the energy sources used for pumping are fossil fuels.

Furthermore, the construction and operation of pumping systems can lead to habitat disturbance and pollution if not properly managed. Addressing these environmental impacts requires careful site selection and the integration of renewable energy sources to minimize environmental effects.

Technological Integration

Integrating smart pump technologies presents both opportunities and challenges. While advanced features, such as variable speed drives and predictive maintenance algorithms, enhance efficiency and control, the initial investment and technological expertise required for implementation may be a barrier for some operators. A comprehensive understanding of the long-term benefits of these technologies is essential to encourage their adoption.

Regulatory Compliance

Finally, compliance with environmental regulations and standards presents a challenge for pump operators. The potential risks associated with pump malfunctions, including leaks and explosions, necessitate effective monitoring systems to ensure safety and environmental compliance. Implementing rigorous monitoring and maintenance practices is crucial for minimizing risks and ensuring pumping operations meet regulatory requirements.

Case Studies

Innovative Solutions in Wastewater Treatment

Numerous case studies demonstrate how innovative solutions have effectively addressed wastewater treatment challenges across various industries. For example, a recent project highlighted the application of advanced pump technology to optimize water use and minimize environmental impact. By utilizing intelligent pump systems, industries were able to significantly improve operational efficiency while reducing energy consumption and maintenance costs.

Pollution and Corrosion Monitoring Systems

The application of specialized monitoring systems has proven vital in managing pollution and corrosion within industrial equipment. A clear flow is collected for real-time monitoring. This system utilizes a thermal probe to assess the impact of heat flow on various metals used in pumps. The test section’s adaptability allows for compatibility with different materials, including stainless steel and brass. These customized solutions enhance equipment lifespan and performance under diverse operating conditions.

Economic and Environmental Benefits of Using Raw Water

Another compelling case study demonstrated the economic and environmental advantages of using raw water for process cooling. This approach not only reduces costs but also minimizes the environmental footprint associated with water treatment. The findings indicated that using raw water can achieve a low environmental impact and high water quality at a significantly lower cost, making it a viable option for industries seeking sustainable practices.