Pneumatic Butterfly Valve Maintenance Guide

Maintenance of pneumatic butterfly valves is essential for the upkeep of water treatment plants. This type of valve is a fundamental component widely used in industrial piping systems for the efficient regulation of gases and liquids. These valves operate through a combination of a rotating disc and a pneumatic actuator, enabling both shut-off and flow control functions. Their versatile design makes them suitable for diverse applications across various industries, such as chemical processing, water treatment, and pharmaceuticals, where precise flow control is critical.

The importance of pneumatic butterfly valves lies not only in their functionality but also in their ability to enhance operational efficiency and safety, thanks to their safety mechanisms and lower maintenance requirements compared to other valve types.

Maintenance of pneumatic butterfly valves is vital to ensuring their optimal performance and longevity. Regular inspections, preventative maintenance, and systematic fault diagnosis are essential practices that help minimize operational problems such as leaks, valve sticking, and actuator failures. Operators are encouraged to adopt a comprehensive maintenance approach, including selecting appropriate materials, adhering to recommended maintenance intervals for component replacement, and utilizing condition monitoring systems to assess performance in real time.

This diligence is critical, as failures of these valves can lead to significant operational disruptions and safety risks. Controversies surrounding pneumatic butterfly valves often revolve around the challenges of ensuring reliability in harsh environments, where factors such as corrosion, material degradation, and improper installation can negatively impact valve performance. Furthermore, the industry’s commitment to various standards and regulations, including API 609 and ASME B16.34, underscores the importance of quality control and compliance in maintaining safety and performance throughout the valve’s lifecycle.

This highlights the need for manufacturers and operators to engage in continuous improvement practices to adapt to emerging challenges and enhance valve designs for future applications.

Design and Function

Pneumatic butterfly valves are essential components in modern industrial piping systems, designed to efficiently regulate the flow of gases and liquids. These valves consist of two main components: a pneumatic actuator and the butterfly valve itself, which features a rotating disc that spins around the valve stem to facilitate operation. This design enables both shut-off and flow control functions, making these valves versatile in various fluid control applications across numerous industries, including chemical processing, water treatment, and pharmaceuticals.

Operating Principle

The operating principle of pneumatic butterfly valves relies on the actuator applying pressure to the valve mechanism, enabling it to open or close in response to control signals. This process ensures a rapid response and reliable operation, which is essential for automation systems requiring precise flow control. The actuator’s connection to the valve stem allows for smooth operation with minimal energy consumption, thus improving performance and conserving resources.

Materials and Design

The design of pneumatic butterfly valves incorporates carefully selected materials for their durability and compatibility with the media being controlled. Commonly used materials include carbon steel, stainless steel, and aluminum bronze for the valve body, while materials such as reinforced PTFE are used for their chemical resistance in the seat. The selected materials must withstand harsh environmental conditions, ensuring a long service life and high reliability.

From a design perspective, the use of advanced materials such as shape memory alloys and ceramics enhances the performance characteristics of these valves, allowing them to operate efficiently under demanding conditions. The adoption of modular design concepts also facilitates component replacement and upgrades, extending the overall system lifespan and enabling performance optimization to meet the requirements of evolving processes.

Design Advantages

Pneumatic butterfly valves have fewer moving parts compared to other valve types, reducing maintenance requirements. Their simple operation also minimizes wear, lowering maintenance and repair costs over time. Furthermore, their safety mechanisms ensure automatic valve closure in case of low air pressure, enhancing safety and reliability in critical applications. The valve body, gasket, and stem should be inspected, paying particular attention to any visible leaks, corrosion, or unusual noises during operation. A thorough inspection should cover five key aspects: appearance, dimensions, sealing performance, pressure resistance, and operating force. Monthly inspections are recommended, with increased frequency in harsh environments or applications with high levels of suspended solids, mineral deposits, or solidified fluids, which can lead to material buildup.

See also: Valve Specifications Based on Water Treatment Plant Type

Preventive Maintenance

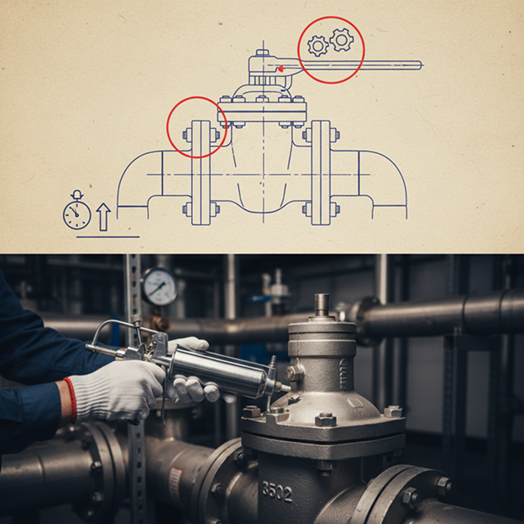

Preventive maintenance practices should include periodic checks of gasket and seal integrity to prevent leaks, ensuring proper lubrication of moving parts according to manufacturer specifications. Particular attention should be paid to the actuator, checking for air leaks, and verifying the operation of control accessories. Periodic calibration of limit switches and limit switches is essential to maintain accurate valve control and prevent unnecessary repetitive operation that can reduce component lifespan.

Troubleshooting

When problems arise, such as leaks, sticking, malfunctions, excessive noise, or actuator issues, a systematic approach to troubleshooting is crucial. For example, if a leak is detected, the seals or gaskets should first be checked for any damage; and if the leak persists, the valve body and disc should be inspected.

Check for any warping or other damage. Periodic monitoring for unusual noises or vibrations can indicate loose components or internal blockages, which must be addressed immediately. In cases of corrosion, it is important to act quickly to prevent further damage, potentially using protective coatings or corrosion-resistant materials on replacement parts. If valves are never operated, they may cease to function over time; therefore, implementing a periodic operating program is essential to maintain their functionality.

Comprehensive Maintenance Practices

A comprehensive maintenance approach, starting with valve selection and continuing through installation, operation, and periodic maintenance, contributes to extending the lifespan of pneumatic butterfly valves. This includes ensuring the selection of appropriate materials for valve manufacturing to minimize problems related to environmental factors, such as humidity and atmospheric corrosives. In general, a combination of regular inspections, preventative measures, and rapid fault diagnosis ensures reliable performance and extended service life for pneumatic butterfly valves.

Common Problems and Solutions

Pneumatic butterfly valves are essential components in fluid control systems across various industries. However, they are susceptible to several operational problems that can negatively impact their performance. Understanding these common problems and their solutions is crucial for maintaining optimal performance.

Valve Sticking

Valve sticking refers to a condition where the valve does not move smoothly, resulting in erratic control responses. This problem often manifests as sudden movement after a period of sticking, which can negatively affect process control.

Causes

- Accumulation of dirt or debris on the valve stem or seat.

- Inadequate lubrication of the control valve joint.

- Excessive gasketing leads to increased friction.

Solutions: Implement a regular schedule for cleaning and lubricating the valve stem and joint to prevent sticking.

Leakage

Leakage in pneumatic butterfly valves can occur in two ways:

- Internal Leakage: Internal leakage occurs when the valve fails to seal properly, allowing fluid to pass through the closed valve disc. This type of leakage often goes undetected until a pressure spike is observed in the flow direction.

- External Leaks: External leaks are visible and occur between the valve body and the atmosphere. Common indicators include drips or puddles around the valve.

Detection and Repair

To identify leaks, visual inspection and ultrasonic leak detectors can be used. Seals are the most common weak point, and regularly tightening flange bolts can help prevent gasket leaks caused by thermal changes and vibrations.

Actor Malfunctions

The actuator is essential for converting control signals into valve movement. Malfunctions can significantly impair valve performance.

Causes:

- Corrosion or damage to the diaphragms in diaphragm actuators.

- Corrosion or piston failure.

- Improper actuator size for the valve.

Solutions: Regularly inspecting the actuator, including the air lines for leaks and overall physical integrity, is crucial. If malfunctions occur, follow component testing procedures and replace parts as needed.

Condition Monitoring and Maintenance Practices

To effectively manage these issues, condition monitoring systems can provide real-time assessments of valve condition, enabling the development of predictive maintenance strategies. Comprehensive documentation of maintenance activities helps identify trends and optimize service schedules. By adhering to established maintenance protocols, including routine inspections and component replacements, operators can significantly improve the reliability and performance of pneumatic butterfly valves, minimizing unplanned downtime and operational disruptions.

Best Care Practices

Effective maintenance of pneumatic butterfly valves is critical to ensuring optimal performance and longevity. A systematic approach to valve care can prevent failures and unplanned downtime while enhancing operational reliability.

Routine Inspections

Routine visual inspections are the cornerstone of proactive valve maintenance. Regular inspections allow operators to identify early signs of corrosion, rust, or leaks, which can lead to catastrophic failures if left unaddressed. Inspections should be performed weekly or monthly, with a focus on critical valves. Conducting checks on the integrity of seals and the efficiency of actuators.

Predictive Maintenance Strategies

Implementing a predictive maintenance system can significantly improve valve management. Monitoring key performance indicators, such as the number of operating cycles and actuator air consumption, allows operators to detect performance degradation early, enabling timely intervention. Additionally, condition monitoring systems provide real-time assessments of valve health, improving maintenance schedules and reducing the likelihood of unexpected failures.

Cleaning and Lubrication

Proper cleaning of the valve and its associated piping is essential for maintaining hydraulic and mechanical performance. Regular valve operation helps remove deposits and contaminants. While the use of synthetic lubricants is recommended to minimize wear on moving parts. Adhering to the manufacturer’s lubrication specifications ensures smoother operation and extends component life.

Component Replacement and Documentation

Regularly replacing consumable components, such as seals, diaphragms, and springs, according to recommended maintenance intervals. It is critical for maintaining optimal performance and preventing damage to other valve components. Documenting maintenance activities, including operating logs and performance trends, provides valuable data for optimizing maintenance schedules and forecasting replacement needs.

Training and Best Practices

Ensuring that maintenance technicians receive adequate training in valve care is crucial for effective operations. Training programs should focus on safe handling, tool use, and early detection of potential problems. Best practices also include storing valves in clean, dry environments and handling them carefully to prevent premature wear. By adopting a supervisory mindset regarding valve maintenance, technicians can elevate their role from mere technicians to guardians of system reliability.

Industry Standards and Compliance

Pneumatic butterfly valves are subject to various industry standards and regulations. That ensures their safe and effective use in a wide range of applications. Compliance with these standards is critical to maintaining performance and safety throughout the valve’s lifecycle. Several key standards govern the design, manufacture, and operation of pneumatic butterfly valves, including:

- API 609: This standard specifies butterfly valves used in petroleum services and ensures they meet essential design and performance standards.

- ASME B16.34: This standard applies to valves used in power and process piping. It provides guidance for their design and performance to ensure reliability in high-risk environments. These standards help establish best practices in valve sizing, installation, and operation, contributing to overall system reliability and safety.

Quality Control and Certification

Implementing effective quality control systems is crucial in pneumatic valve manufacturing. This includes dimensional inspections, material verifications, and performance testing to ensure compliance with required specifications before shipment. Additionally, products are often certified to international standards such as ISO 9001 and CE. Enhancing the quality and reliability of valves available on the market.

Traceability systems are critical, enabling manufacturers to track materials and production processes throughout the product lifecycle. This capability supports quality improvement initiatives and facilitates fault analysis when problems arise. Thus, it improves the overall service life of pneumatic valves.

Continuous Improvement and Compliance

Manufacturers are encouraged to engage in continuous improvement programs based on field performance data and customer feedback. These initiatives ensure that design and manufacturing processes are regularly updated to address emerging challenges and improve valve performance over time. This is achieved through adherence to established standards and the adoption of a culture of quality and continuous improvement. Manufacturers can significantly extend the service life of pneumatic butterfly valves, ensuring they meet the requirements of modern applications.