How MBBR Technology Powers Industrial Wastewater Treatment Plants

Moving Bed Biofilm Reactor (MBBR) technology is an advanced biological wastewater treatment process that uses free-floating plastic media, or biofilm carriers, to support the growth of microbial communities capable of degrading organic pollutants. This innovative approach is efficient and adaptable to complex and variable wastewater streams, making it particularly suitable for industries with stringent discharge regulations and varying water quality. MBBR systems are increasingly adopted in sectors such as food and beverage, chemical manufacturing, and textile production, where effective management of high organic loads is critical for environmental compliance and sustainability.

MBBR Technology Principles

The MBBR technology, or moving bed biofilm reactor, is an advanced biological wastewater treatment process designed to effectively handle complex wastewater streams. This technology uses free-floating plastic media, also known as biofilm carriers, to support the growth of microbial communities that degrade organic pollutants in wastewater. This process is characterized by its efficiency and adaptability compared to conventional treatment methods.

Mechanism of Operation

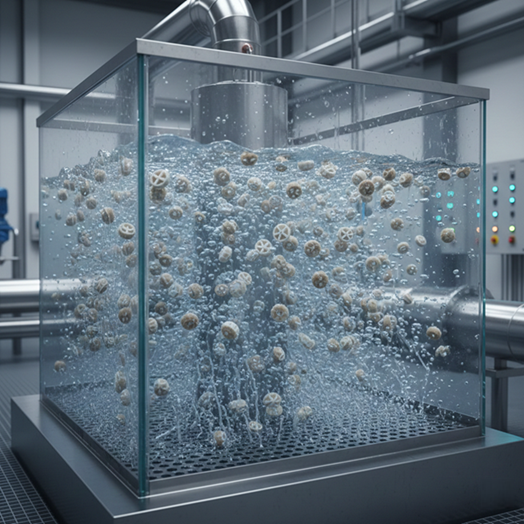

In an MBBR system, the biofilm carriers maintain continuous movement, typically through aeration or mechanical mixing. This movement ensures optimal contact between the biofilms, composed of microorganisms, and the wastewater, facilitating penetration. This reduces pollutants such as chemical oxygen demand (COD), biological oxygen demand (BOD), and ammonia. Unlike conventional activated sludge systems, MBBR technology does not require sludge recycling, simplifying operations and reducing maintenance requirements.

A more detailed explanation of the MBBR wastewater treatment mechanism is available.

Advantages of Industrial and Sanitation Wastewater Treatment Plants

The compact design of MBBR technology enables high treatment capacity in a limited space, reducing land use and operating costs, while ensuring reliable performance even under fluctuating incoming water quality.

- Affordable Cost: Very low capital and operating costs.

- Highly competitive investment for new facilities.

- Reduced sludge production and improved quality. Compact size compared to similar products.

- Swift installation: Quick and straightforward installation with minimal on-site preparation.

- Custom-designed to meet client requirements.

- Easy operation: Requires minimal maintenance.

- Flexible and innovative technology.

- The open and protected biofilm holder design offers a superior effective surface area and prevents holder blockage.

- Unique aeration and mixing pattern.

- Durable and stable: Rapid recovery and resistance to disturbances (hydraulic and toxic).

- Long media lifespan.

- Environmentally friendly: Energy-efficient. Odorless operation.

The compact design of MBBR technology is particularly suitable for facilities with limited space or those handling high organic loads. The biofilm flexibility of MBBR systems allows them to maintain consistent treatment performance even under shock loads or changes in inlet flow quality, ensuring compliance with stringent discharge regulations. Furthermore, MBBR systems produce less sludge compared to conventional methods, reducing sludge handling and disposal costs.

Operational Stability and Maintenance: MBBR technology is known for its operational stability, requiring less ongoing maintenance than other biological treatment systems. The self-regulating nature of the biofilms reduces the need for intensive operator intervention, although operators must have a deep understanding of the process to effectively monitor performance.

Components of Moving Bed Biofilm Reactor (MBBR) Systems

- Fine Screening Drum: Used to reduce suspended solids in the water, it is made of stainless steel with narrow 5 mm diameter openings and is designed for self-cleaning.

- Dissolved Air Flotation Unit: Removes suspended solids, biological oxygen demand (BOD), and oils from wastewater. Contaminants are removed by tiny bubbles that adhere to them and lift them to the surface.

- MBBR Biological Reactors: Contain a biological medium that increases the surface area for microbial growth. An air aeration network is distributed via diffusers to ensure bacterial growth and water treatment.

- Settling Tank: Used after aerobic treatment, solids are separated and collected at the bottom of the conical-base tank. Filtration: Water from the chlorination tank is purified through filters containing sand and carbon media to remove sediment and odors.

- Sludge Tank: Sludge is treated in a dedicated tank with aeration to concentrate it before being transferred to drying ponds or a landfill.

A moving-bed membrane bioreactor (MBBR) system consists of several key components that work together to effectively treat wastewater. Each element plays a crucial role in ensuring optimal performance and efficiency in the biological treatment process.

Biofilm Carriers

Biofilm carriers are essential components of a moving-bed membrane bioreactor system, providing surfaces for microorganisms to adhere to and grow. These carriers are typically made of plastic materials such as crude polyethylene, which has a density similar to water, allowing them to remain suspended throughout the treatment tank. Their design optimizes the surface area available for microbial colonization, facilitating the efficient decomposition of organic matter and pollutants in wastewater.

Aeration Network

The aeration network is another vital component in moving-bed biofilm reactor systems. This system serves a dual purpose: first, it injects oxygen into the wastewater, promoting the aerobic conditions necessary for microbial activity; second, it creates movement within the tank, ensuring the continuous movement and distribution of biofilm carriers throughout the water. This movement enhances contact between the biofilm carriers for microorganisms and wastewater, thus improving waste decomposition efficiency.

Sieve

The sieve is a key feature that keeps the biofilm carriers within the system while allowing the treated water to flow through. It is designed to allow water to pass through while preventing the escape of microorganisms attached to the carriers. This containment is essential for maintaining a stable bacterial count, which is critical for the continuous decomposition of organic matter in the incoming water.

Media Movement

The mechanism that ensures the continuous movement of the biofilm carriers is a fundamental element in the design of an MBBR reactor. Continuous media movement enhances contact with the wastewater and prevents carrier settling, which can impede treatment performance. The balance between media density and water movement is critical to ensuring the overall effectiveness of the system.

System Flexibility

Moving bed biofilm reactor (MBBR) systems are flexible, allowing operators to select specific media sizes and configurations to suit various applications and water flow characteristics. This flexibility makes the moving-bed biofilm reactor an ideal choice for various industries, including textiles and chemicals, where the composition of wastewater can vary significantly.

Industrial Wastewater Treatment Applications

Moving-bed biofilm reactor (MBBR) technology is increasingly used across various industrial sectors for wastewater treatment due to its effectiveness in handling high organic loads and its compact design.

Food and Beverage Industry

In the food and beverage sector, MBBR technology is widely used to treat wastewater with a high biochemical oxygen demand (BOD). It effectively removes contaminants from dairy, meat, and beverage production facilities, enabling companies to achieve superior wastewater treatment while minimizing their environmental impact. For example, dairy processing plants use MBBR systems to treat wastewater generated from milk, cheese, and yogurt.

Chemical and Pharmaceutical Manufacturing

MBBR systems are also used in the chemical and pharmaceutical industries, where wastewater often contains high levels of organic pollutants. These sectors benefit from MBBR’s ability to efficiently break down complex waste materials, such as solvents and other chemicals.

Chemical manufacturing facilities are increasingly integrating MBBR technology into their wastewater treatment processes to meet stringent regulatory requirements before discharging wastewater into natural waterways.

Textile and Dairy Industries

Textile mills, known for producing wastewater laden with dyes and pollutants, have also found MBBR systems to be a viable option due to their compact size and effective pollutant removal. Additionally, the dairy industry continues to adopt MBBR technology to meet its wastewater treatment needs, responding to increasing wastewater standards and the demand for sustainable food production practices.

Distilleries

MBBR technology has also proven beneficial in the distillery industry. It is particularly in bourbon distilleries facing challenges related to increased water demand and compliance with wastewater regulations. By implementing moving-layer biofilm reactor (MBBR) systems, these facilities can manage the high levels of biochemical oxygen demand (BOD) and total suspended solids (TSS) generated during production. That reduces the flow and organic load on municipal wastewater treatment plants.

Read also: Why choose MBBR technology for improved wastewater treatment?