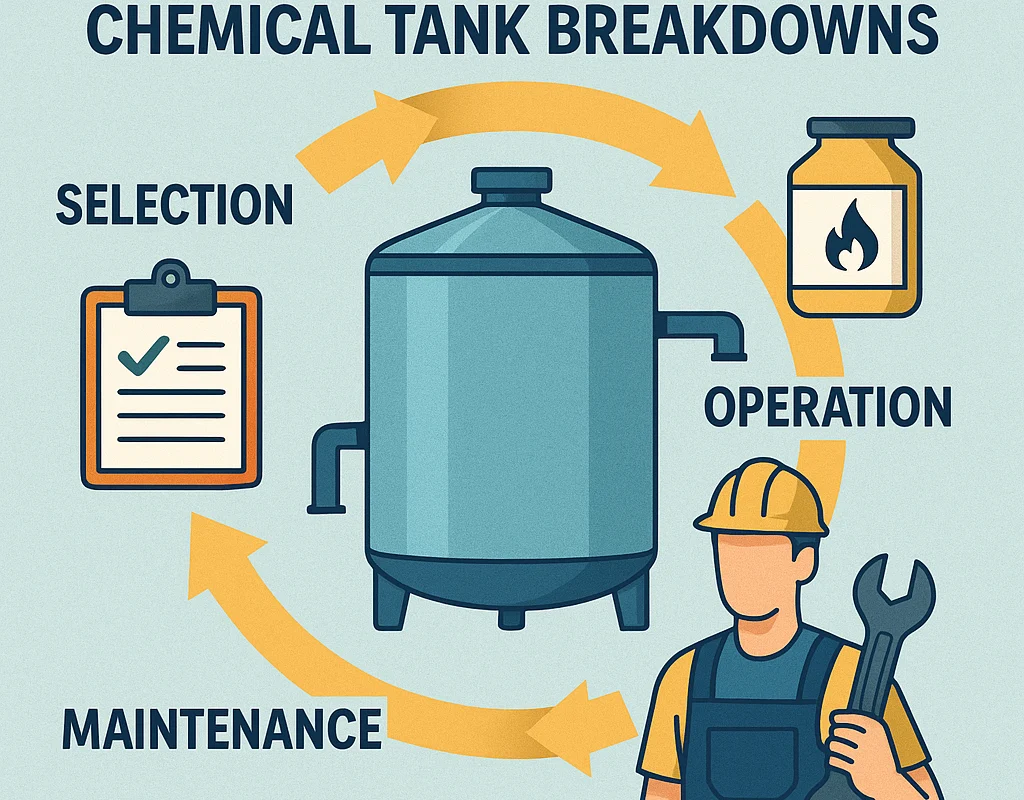

From Selection to Maintenance: Integrated loop to reduce chemical tank breakdowns

The full-loop chemical tank management system encompasses a comprehensive process of selection, implementation, and maintenance aimed at reducing downtime and enhancing operational efficiency. This approach recognizes that the longevity and reliability of chemical storage systems depend on careful planning and implementation at every stage of the tank lifecycle. It is important to note that the selection of appropriate tank materials, sizes, and designs must be compatible with the specific chemicals being stored to prevent harmful interactions and potential safety hazards.

Critical factors influencing the selection process include chemical compatibility, tank capacity, and regulatory compliance. The materials used in tank construction—such as stainless steel, fiberglass reinforced plastic, and polyethylene—play a pivotal role in both durability and safety, while adherence to local safety codes ensures compliance with industry standards.

Maintenance strategies are critical, including periodic inspections, cleaning protocols, and preventative maintenance plans to mitigate risks associated with handling chemicals. A well-established maintenance schedule helps identify and resolve potential problems early, extending tank life and ensuring safe operations.

However, challenges such as corrosion, structural weaknesses, and access issues remain, requiring innovative design and effective management practices to overcome these obstacles and maintain system integrity.

As industries move toward more sustainable practices, the trend toward smart chemical management solutions is gaining momentum, driven by technological advancements and an increased focus on operational efficiency. Continuous improvement through performance tracking and feedback mechanisms plays a critical role in optimizing these systems and ensuring they respond to evolving market demands and safety standards.

Chemical Tank Selection

Selecting the right chemical tank for industrial applications is critical to ensuring safety, compliance, and operational efficiency. This selection process involves evaluating several key factors to align tank specifications with the requirements of the chemicals to be stored or processed. Factors to Consider:

- Chemical Compatibility

- Tank Size and Capacity

- Material Selection

Important Article: Guide to Choosing the Ideal Chemical Tank

Design Considerations: Structural Integrity and Pressure Design

When selecting a tank, it is essential to ensure its ability to withstand internal and external pressures, as well as environmental factors. Considerations should include wall thickness, foundation design, and structural shape—cylindrical tanks often provide better pressure distribution than rectangular tanks.

Additional Factors

Factors such as wind and seismic loads, especially for outdoor installations, should also be considered to ensure safety and long-term performance.

Regulatory Compliance

Compliance with local safety laws and regulations is critical in the selection process. Regulations governing chemical storage practices may vary by region, and it is advisable to carefully review these requirements before selecting and installing a tank. Compliance not only helps mitigate risks but also supports operational safety and enhances the safety of personnel and the environment.

The Integrated Loop Concept

The integrated loop concept in chemical tank management focuses on the seamless integration of tank system selection, implementation, and maintenance to improve efficiency and reduce downtime. This holistic approach recognizes that effective chemical management requires careful consideration at every stage of the tank lifecycle, from initial selection through ongoing maintenance practices.

Selection and Implementation

Selecting the right tank involves evaluating various factors, such as tank size, construction materials, and capacity, to ensure it aligns with project needs and product characteristics. Proper selection is critical, as it lays the foundation for effective chemical management. Additionally, advanced technologies, such as Internet of Things sensors, can be incorporated during the implementation phase to enhance monitoring and operational efficiency.

Maintenance Strategies

Periodic inspections and maintenance are critical to maintaining tank performance and safety. Developing a comprehensive maintenance schedule, including visual inspections, integrity tests, and component safety assessments, helps reduce the risks associated with handling chemicals.

Implementing safety measures and following best practices can also enhance the safety and reliability of tank operations.

Digital Transformation

Integrating smart technology into chemical management systems promotes a data-driven approach to operations. For example, digitizing chemical management can include the use of monitoring dashboards that provide real-time visibility into tank conditions and operational metrics. This enables operators to manage exceptionally well, focusing on critical issues as they arise, thereby improving overall efficiency.

Continuous Improvement

The integrated loop requires continuous monitoring and process improvement. Using performance tracking systems, organizations can identify areas that need improvement and implement regular updates to maintain system efficiency.

Operator and maintenance staff feedback plays a critical role in improving operations, ensuring that operations continue to respond to evolving market demands and technological developments.

Implementation Strategies

Comprehensive Planning

Effective implementation of chemical storage solutions begins with comprehensive planning. A thorough needs analysis, along with a technology assessment and ROI calculation, is essential to identify areas that will benefit most from smart technology improvements. This initial step is critical to ensuring the compatibility of the selected technologies align with the organization’s objectives and existing operational frameworks.

Training and Integration

To maximize the benefits of new technology, organizations must invest in effective training and integration programs. Employees must receive appropriate training to facilitate a smooth transition to smart manufacturing systems, while implementation must be phased to maintain operational stability. Considering current requirements and future scalability during system integration is critical to adapting to evolving market demands.

Monitoring and Optimization

Continuous monitoring and optimization of smart systems is critical to sustainable success. Implementing performance tracking systems allows organizations to identify areas for improvement while keeping systems up-to-date through regular maintenance and upgrades. Gathering feedback from operators and maintenance personnel also promotes continuous improvement of processes and procedures, ensuring continued operational efficiency.

Management by Exception

In chemical management operations, the practice of management by exception helps optimize resources and improve operational efficiency. By focusing only on problem locations, organizations can prioritize their attention and resources more effectively. Remote data collection on pumping rates and tank levels enables the organization to better understand the risks and impacts of these risks. In addition to using anomaly alarms, operators can proactively address potential problems, reducing unnecessary manual inspections.

Emerging Technologies

The adoption of emerging technologies, such as advanced robotics, 3D printing, and blockchain tracking solutions, presents new opportunities to improve chemical management practices. These innovations not only improve operational efficiency, but also facilitate better training programs and improve supply quality.

Transparency in Chemical Use

Companies must remain adaptable to effectively leverage these developments while minimizing the risks associated with technological complexity.

Chemical Design Considerations

A chemical storage system must be designed to suit the characteristics of the chemicals in question. This includes considering factors such as compatibility, capacity, and material selection to prevent serious failures and ensure safe and sustainable storage solutions. A well-designed storage tank, which takes into account the nuances of the chemicals stored within, is critical to maintaining the integrity of the entire chemical delivery system.

Maintenance Best Practices

Effective maintenance practices are critical to ensuring the integrity and longevity of chemical storage tanks. A comprehensive preventive maintenance plan should be developed, outlining the specific inspections and maintenance tasks that should be performed regularly on tanks and vessels. These tasks generally include cleaning, lubrication, inspections, testing, repairs, and replacements, and are scheduled based on the age of the equipment, operating conditions, and manufacturer recommendations.

Cleaning Protocols

Regular tank cleaning is critical to maintaining chemical purity and preventing structural damage. The cleaning process should include thorough tank drainage, removal of sediment, and cleaning of the interior walls. Best practices for industrial tank cleaning include a thorough inspection of the tank. Washing it with appropriate cleaning chemicals, rinsing it with clean water. And re-inspecting it for any residual contamination.

In addition, some stainless steel tanks may use clean-in-place (CIP) systems to facilitate automated cleaning, reducing downtime compared to manual cleaning methods.

Frequency of Inspections and Maintenance

The frequency of inspections and maintenance depends on various factors. Including the type of tank or vessel and the specific components used. As a general guideline, inspections and maintenance should be performed at least annually, with more frequent inspections of critical equipment.

Regular visual inspections are essential to detect any signs of leaks, corrosion, or damage to the tank and its surroundings.