Gate Valve Maintenance in Water Treatment Plants

In the world of water treatment plants, where systems handle raw water laden with suspended solids, chemically treated water, and corrosive wastewater, the gate valve stands out as the most reliable sealing element. Unlike butterfly valves, where rubber O-rings can be quickly affected by large impurities, the gate valve provides a tight metal or rubber seal, preventing the direct flow spurt when opened. However, this “buried” design within the valve body means that its maintenance requires in-depth technical knowledge and experience in handling high hydraulic pressures.

Related article: Chemical Corrosion Risks in Desalination Plants and How to Choose the Right Materials to Combat High Water Salinity

Part 1: The Different Operating Mechanisms of Gate Valve Types

To understand maintenance, it is necessary to first classify the valves present in the plant, as each type presents different maintenance challenges:

Rising Stem Gate Valve

This type is visually easy to maintain; when the valve is opened, the stem rises upwards.

- Maintenance Challenge: The stem is constantly exposed to the station’s external environment (humidity, chlorine gases, dust). This necessitates a continuous protective layer.

- Advantage: You can determine the valve’s status (open/closed) from 50 meters away simply by observing the stem’s length.

Non-Rising Stem Gate Valve

Here, the stem rotates within the valve body to move the gate.

- Maintenance Challenge: You cannot see the stem’s condition or corrosion because it is submerged in water. Maintenance requires a “mechanical sense” when rotating it.

- Advantage: Ideal for confined spaces and underground (buried chamber valves).

Part 2: Root Cause Analysis

Maintenance is not limited to repair; it involves understanding “why the valve failed.”

Erosion and Wire Drawing Phenomenon

When a gate valve is misused for throttling instead of complete sealing, water flows at excessively high speeds through a narrow opening below the gate.

- Impact: This leads to the carving of fine, wire-like grooves in the valve seat, causing the valve to leak even when closed with maximum force.

- Maintenance Lesson: If these signs are present, operators should be informed that this valve is for isolation only and not for calibration.

Sedimentation Trap

The gate valve body has a recess at the bottom where the gate rests. In raw water treatment plants, this recess becomes a “sand trap.”

- Impact: Over time, the sand hardens and prevents the gate from reaching the zero point.

- Technical Solution: Install small bypass valves to clear the channel, or use a flexible seat design that allows for sediment compression without damage.

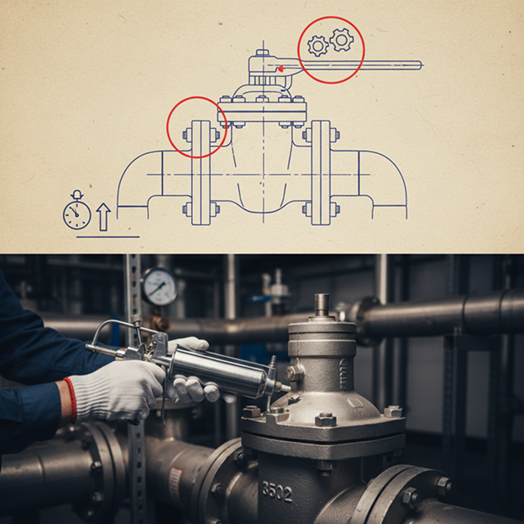

Part 3: Comprehensive Maintenance Steps (Step-by-Step Guide)

Stage 1: Inspection and Preparation

Before loosening a single screw, a live inspection must be performed:

- Use a stethoscope to detect a hissing sound, which indicates an internal leak.

- Measure the valve body temperature; a sudden temperature difference between the front and back of a blocked valve indicates a hydraulic leak.

Stage 2: Dealing with the Packing Box

If there is a stem leak, follow these steps carefully:

- Cleaning: Remove all rust from the stem before pressing it in to avoid damaging the new packing.

- Adding, not replacing: Often, you can add a new packing ring over the old one if the overall condition allows.

- Squaring: Ensure the packing rings are cut at a 45-degree angle and the holes are offset to prevent water from passing through.

Stage 3: Removing the Bonnet and Internal Maintenance

When absolutely necessary to remove the valve:

- Gate Position: Lift the gate slightly before unscrewing the bonnet. Removing the bonnet with the gate completely closed may cause it to jam or break the wedges.

- Inspecting the Wedge: Look for signs of pitting. If the gate valve is rubber-coated (EPDM), check for cracks caused by chemicals (such as ozone or chlorine at high concentrations).

- Clean the seats: Use non-abrasive cleaners. Remember that even a few microns of scratching indicates a failure of the pressure test.

Part 4: Maintenance of Electric and Hydraulic Actuators

The large valve cannot be opened manually. Actuator maintenance is just as important as the valve itself:

- Torque Switch Calibration: The actuator must be set to stop before it breaks the stem. If the valve requires 500 Nm to close, the switch must be set to a maximum of 550 Nm.

- Oil Check: Actuators contain gearboxes. Ensure that the gear oil is not mixed with water (it will appear milky), which indicates a damaged oil seal.

Part 5: Gate vs. Butterfly Valve Maintenance Comparison

Disassembly Difficulty:

- Butterfly: You can completely disconnect the valve from the line in one hour.

- Gate: Large valves (greater than 24 inches) may require a crane and a full crew. As the weight of the gate and cover alone can exceed one ton.

Spare Parts:

- Butterfly: Often, the entire valve or the rubber core needs to be replaced.

- Gate: These are “forever repairable” valves; the seats can be re-welded and machined. Only the stem can be replaced, saving the cost of purchasing a new valve.

Self-Cleaning:

- Butterfly valves “clean themselves” as the flow passes around the disc.

- Gate valves require “operational maintenance” through frequent opening and closing to expel suspended solids.

Previous article: A guide to pneumatic butterfly valve maintenance

Part 7: Golden Tips and Strategies for Extending Valve Life

Extending the lifespan of gate valves in harsh treatment plant environments doesn’t stop at repair; it starts with adopting a “proactive maintenance culture.” Here are some essential tips to ensure your valve remains in service for as long as possible.

Epoxy Integrity Protection Protocol:

In processing plants, epoxy coating acts as a chemical defense, not just an aesthetic touch. The presence of gases like hydrogen sulfide (H₂S) or high humidity can corrode the valve body and cause the bolts connecting the cover to the body to break down. The coating should be inspected periodically, and any scratches should be treated immediately with a “cold epoxy” coating to prevent the formation of deep rust pockets that can eventually lead to microscopic holes in the valve body, forcing complete replacement.

Digital Logbook Automation:

A processing plant cannot be managed efficiently without a “Valve ID” for each valve. This logbook should record the number of operating cycles, as each opening and closing represents a portion of the lifespan of the gaskets and stem. The logbook helps predict when a valve might fail. If you notice that a particular valve requires gasket tightening every month instead of every year, this indicates stem misalignment that needs immediate correction before it breaks.

Stem shielding and weather protection:

Valves installed in the open are susceptible to UV radiation and acid rain. Placing protective caps or even simple plastic tubing over the rising stem protects the grease from drying out and hardening into an abrasive solid. Field studies indicate that stem covering reduces grease consumption by up to 70%. It protects the bolts from freezing and rusting, making emergency disassembly much faster and easier. It protects technicians from the dangers of using excessive force.

Preventing dry running and training operators:

Operating crews must be made aware that a gate valve is designed to operate in a lubricated, immersed environment. Closing the valve too quickly with long hand-held torque wrenches (cheater pipes) creates concentrated stresses on the sealing points that can cause them to warp. Maintenance begins with ensuring that everyone who touches the steering wheel understands that “force is not the answer,” but rather smooth and consistent operation.

Conclusion

Maintaining gate valves in water treatment plants is a blend of art and engineering. It’s not simply “tightening screws,” but a strategy that begins with proper operation and ends with meticulous inspection of internal components. A skilled technician is one who can hear the valve’s sound and feel the stem’s torque, identifying the problem before it escalates into a disaster that could flood the plant or cut off water supplies to thousands of customers.