Challenges and Limitations of Moving Bed Biofilm Reactor (MBBR) Technology

Despite the numerous advantages offered by moving bed biofilm reactor (MBBR) technology in wastewater treatment. It also faces several challenges and limitations that operators must consider to achieve optimal performance.

Operational Fluctuations

One of the main challenges facing moving bed biofilm reactor systems is their sensitivity to operational fluctuations in pollutant concentrations and ions within the wastewater. Changes in inlet and outlet flow conditions, as well as the presence of toxic pollutants. It can negatively impact biological activity within the reactor. These fluctuations require careful monitoring and adjustments to maintain efficient treatment performance.

Biofilm Management

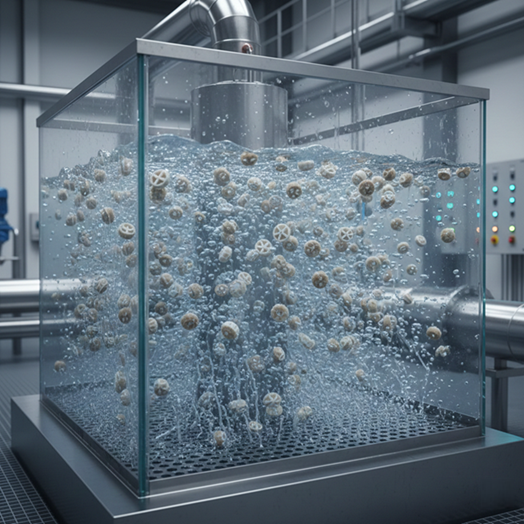

Biofilm formation and maintenance are critical to the efficiency of MBBR reactor systems. However, maintaining optimal conditions that promote biofilm growth can be challenging. For example, biofilms must be thin and evenly distributed to ensure adequate substrate and oxygen transport.

Thick or uneven biofilms can hinder the processing, reducing the overall system efficiency. Managing biofilm thickness and ensuring proper adhesion to the carrier media requires ongoing attention and expertise.

Material Considerations

The type and density of the carrier media used in MBBR reactor systems can significantly impact performance. Recycled materials, while often more economical, can cause variations in their properties. Potentially affecting media durability and mobility under operating conditions. This variation can lead to issues such as contamination and inadequate biological contact, negatively impacting processing efficiency.

Furthermore, concerns about the release of harmful substances. Such as bisphenol A (BPA) or phthalates, from plasticizers during regranulation pose additional risks, particularly in sensitive applications like aquaculture.

Design and Implementation Challenges

The design and implementation of multi-membrane proton reactor systems require careful consideration of various factors. It is including the active surface area of the carrier media and the overall reactor configuration. Miscalculations in these areas can lead to reduced biodegradation efficiency, resulting in suboptimal treatment outcomes. It is essential that operators collaborate with experienced specialists to provide guidance throughout the design, construction, and maintenance phases of the system.

Maintenance Requirements

Although multi-membrane proton reactor (MBBR) systems are designed for low maintenance, they are not entirely maintenance-free. Periodic inspections and adjustments are necessary to ensure proper aeration and even distribution of the carrier media throughout the reactor. Inadequate maintenance can lead to increased downtime and operating costs, diminishing the benefits of this technology.

Case Studies of Several Industrial Applications

MBBR (Moving Bed Biofilm Reactor) technology has been successfully implemented across various industrial sectors, demonstrating its versatility and effectiveness in wastewater treatment.

Beverage Industry

In a notable case, a South American soft drink manufacturer faced challenges due to a significant increase in production volumes. To address the instability of water flows, environmental experts modified the company’s wastewater treatment system to meet the new operating conditions, demonstrating MBBR’s ability to effectively manage fluctuating flows.

Dairy Industry

A leading dairy company invested in upgrading its Struckhausen plant to produce whole and skimmed milk powder for infant formula. An environmental expert was tasked with expanding and improving the existing wastewater treatment system, implementing MBBR technology to ensure compliance with stringent discharge regulations and enhance treatment capacity.

Semiconductor Industry

In the semiconductor industry, companies face increasing challenges in optimizing water use and treatment processes. MBBR technology has emerged as a game-changer, enabling the development and use of innovative wastewater treatment technologies that ensure the sustainable and economical use of water in high-tech manufacturing processes.

Landfill Leachate Treatment

MBBR technology was also implemented to improve landfill leachate treatment. A landfill case study highlighted a significant reduction in odors and effective leachate treatment, underscoring the ability of MBBR technology to handle complex waste streams.

Similarly, a sanitary landfill recorded a remarkable 209% increase in processing capacity through the implementation of MBBR processes, highlighting the need for more efficient and sustainable solutions at a rapid pace. With the growing demand for advanced technologies, membrane bioreactors (MBRs) and moving-layer bioreactors (MBBRs) are emerging as key players in the industry, promising substantial improvements in processing efficiency and effectiveness while addressing contemporary challenges such as environmental regulations and emerging pollutants.

Advances in Moving-Layer Bioreactor Technology

Moving-layer bioreactor technology has gained significant traction due to its ability to enhance the removal of organic matter and nutrients while reducing energy consumption. The system design allows for flexibility in handling varying flow conditions, making it ideal for facilities experiencing fluctuating loads.

Recent advancements in moving-layer bioreactor (LMB) systems emphasize small footprint and ease of retrofitting, enabling existing treatment plants to upgrade their infrastructure without extensive renovations.

Innovative Features and Applications

New features in mobile layer bioreactor (MBBR) systems, such as high biomass concentrations and specialized media carriers, facilitate rapid treatment with low hydraulic retention times. This efficiency enables MBBR systems to treat wastewater much faster, often within a few hours, while maintaining high treatment standards.

Learn more about the advantages of MBBR technology in wastewater treatment in this article: Why is MBBR Technology Preferred? Furthermore, the ability to integrate MBBR with various post-treatment separation processes gives operators greater flexibility and control over treatment outcomes.

Addressing Contemporary Challenges

With the increasing pressure on the semiconductor industry and other water-intensive sectors to optimize water use and treatment processes, MBBR technology is emerging as a viable solution. Traditional methods often struggle to handle emerging contaminants, including pharmaceuticals and personal care products, which cannot be effectively removed by conventional treatment systems. The robust design and operational efficiency of MBBR enable it to become a transformative approach to addressing these challenges and supporting more sustainable water management practices.

Future Research and Development

The continued development of MBBR technology is expected to be driven by ongoing research and development efforts aimed at improving treatment efficiency and reducing operating costs. Companies are increasingly focusing on innovative treatment systems and integrated solutions to meet the stringent requirements of various industries while promoting environmental sustainability. As these developments materialize, MBBR technology is expected to play a crucial role in shaping the future of wastewater treatment systems globally.

Conclusion

In conclusion, MBBR technology remains a promising strategic solution in the field of wastewater treatment. Despite the operational challenges associated with managing biofilms and the system’s sensitivity. Its high flexibility and successful applications across various industrial sectors clearly outweigh these challenges. Ongoing technological advancements promise a more efficient and sustainable future for these systems. Therefore, focusing on research and development will not only help overcome current limitations. It will also solidify MBBR’s position as a cornerstone of global water resource management. Achieving the necessary balance between economic efficiency and environmental compliance.